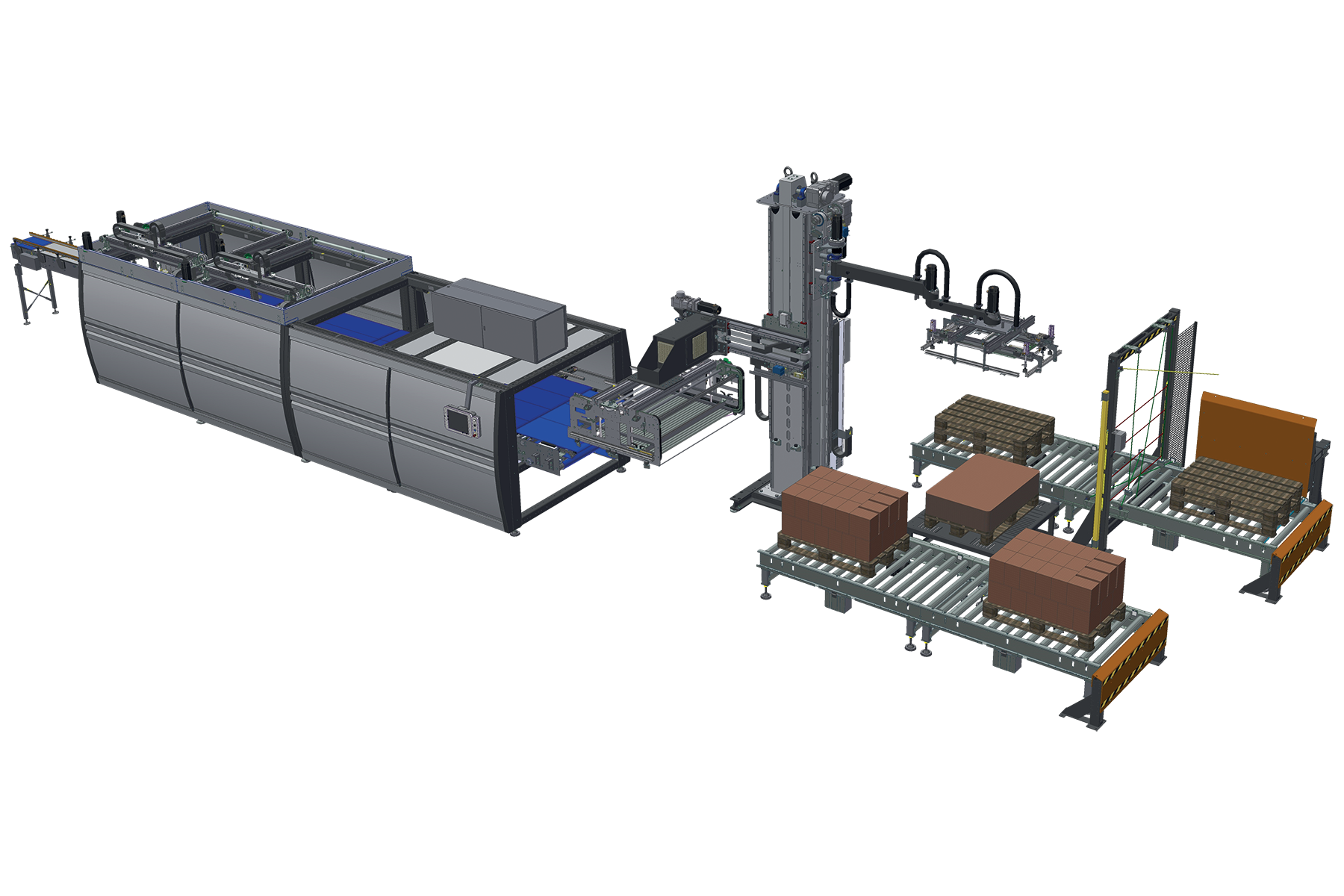

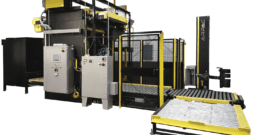

The central column is actuated by brushless motors, which guarantee highly dynamic, reliable and precise movements of all axes of operation. The employment of this technology within palletization systems, which are characterized by repetitive actions, turns into higher reliability, fewer maintenance operations and lower operating costs.

The machine automation and control are entrusted to the innovative Sercos Fieldbus technology, featuring an intuitive user interface for quick and easy management of end-of-line palletizing operations. A touch-screen display with advanced graphics and a complete array of utilities for real-time machine diagnosis and technical support further enhance the machine control features. In addition to that, the HMI will display automatically all possible palletization patterns just by entering the pack size and specifications, and the number of layers required.

The accurate design of the column and of the horizontal beam, along with the creeping on recirculating-spheres skids, ensures fluid and uninterrupted movements, with nearly no dynamic buckling and virtual absence of vibrations: this is the key factor to be able to guarantee a lengthy life cycle of the mechanical components.

The APS range of SMI palletizers is equipped as a base supply with the brand-new dedicated “safety PLC”, which allows to program all protection systems in a flexible, reliable and efficient manner. The PLC monitors the accurate functioning of all safety devices, integrating their performances, for a safe intersection between areas of handling inside the machine perimeter. This system enables to dramatically reduce machine downtimes, both in an emergency and during the pallet loading operation, the cardboard sheet loading operation, etc., thanks to dedicated solutions for each area of intervention. Maintenance operations are simple and easy, and the palletizing systems adaptation to future safety rules will be quick and troublefree as just an upgrade of the PLC software will be required.

APS palletizing systems easily integrate into existing packaging lines or into new plants and can be set in motion immediately, since each single module composing the palletizer, conceived as an independent unit, is connected through a network to the central body. Thanks to this designing feature, each module is assembled, pre-cabled and tested at SMI production plant, thus minimizing assembly and start up operations at the customer’s site. For example, the central body can be easily disassembled, conveyed or stored in a small room, and later re-assembled and set in motion again in less than 5 hours. The mechanical simplicity, the employment of robot-based components and the structural optimization allow a remarkable reduction of the maintenance costs and of the energy consumption, as well as the extension of the machine life cycle.