Automatic Platform Pallet Stretch Wrapper

| Condition | New |

| Category | Pallet Wrappers - Stretch Wrappers, Wrappers - Wrapping Equipment |

| Manufacturer | Arpac |

| Model | PAC-4R5 |

| Industry | Beverage, Brewery, Consumer Products, Dairy, Distillery, Food, Nutraceutical, Winery |

| Location | North America |

The Automatic Platform Pallet Stretch Wrapper is part of a robust line of stretch wrapping equipment designed to maximize stretch film usage while ensuring the very best load unitization. This equipment is constructed with heavy-duty reinforced structural steel with non-corrosive baked on powder coat finish,to guarantee years of reliable wrapping.

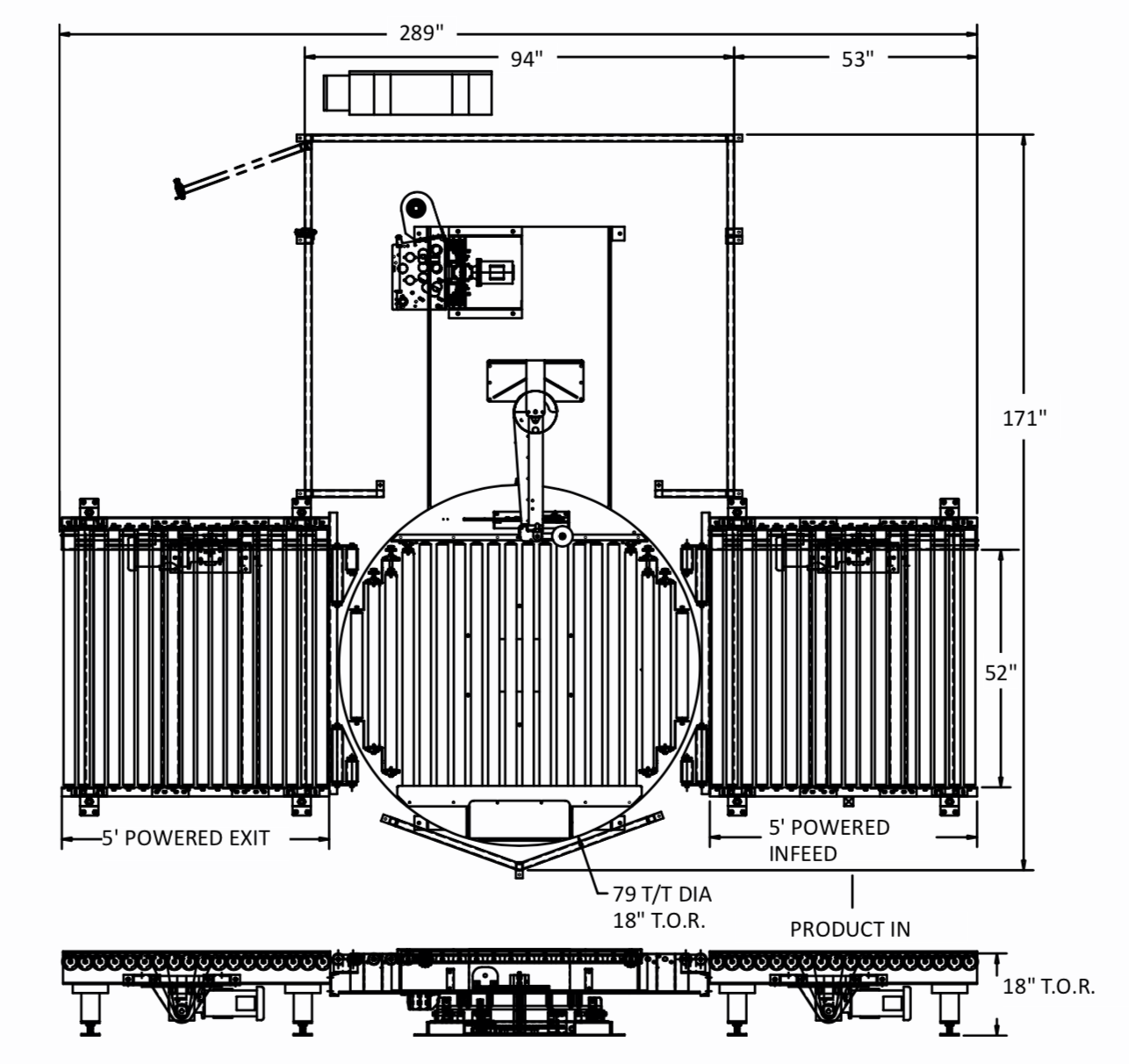

(Min. Load Size 30″W x 30″L x 24″H) (Max Load Size 48″W x 48″L x 65″H) (Max Load Weight 4,000lbs.)

The Automatic Platform Pallet Stretch Wrapper provides superior performance around-the-clock. Ideal for high speed conveyorized production lines, this inline system indexes pallet loads automatically into and out of the wrap zone and discharges loads without operator assistance. At the end of the wrap cycle, the wipe arm aligns the film with the clamp arm. Once the clamp arm captures the film, the hot wire cuts the film and the wipe arm makes a secondary motion, wiping the film onto the load to prevent film tails from unraveling.

Rugged power roller conveyors are used for passing loads through the wrap zone. These conveyors are driven by ANSI chains and are guarded with heavy gauge formed sheet metal. The Roping device is used as a replacement for belly straps and stabilizes the load, and a Top Sheet Dispenser covers the top of the pallet with film, for additional product protection from moisture.

| Turntable Speed | 15 rpm |

| Conveyor Speed | 30 ft/s |

| Electrical Power Requirements | 220 VAC, 3 Ph, 60 Hz, 20 A |

| Pneumatic Power Requirements | 80 psi, 3 SCFM |

| Approx. Shipping Weight | 4950 lb |

| Load Height | 24 to 65 in |

| Load Capacity | 4000 lb |

| Load Width | 30 to 48 in |

| Load Length | 30 to 48 in |

Core Features :

- Heavy-duty reinforced structural steel construction for around-the-clock operation

- Powder coat finish that provides a durable scratch resistant surface and prevents corrosion

- Allen-Bradley® HMI for machine parameter settings, manual operations and fault diagnostics messages

- Electronically controlled film tension adjustment

- Top over-wrap control

- Adjustable top and bottom wrap counters (0-7)

- Turntable drive: 3/4 HP DC motor with ANSI 60 chain

- Heavy duty conveyors with 2.5″ rollers, 11 gauge wall spaced at 3.75″ pitch driven by “loop to loop” ANSI chain

- Driven turntable transition rollers for more positive pallet handling

- Unique 36″ diameter precision steel ring turntable support for stable load entry and exit

- Manual conveyor controls

- Mechanical lock holds turntable in position during product transfer

-

- Heavy-duty reinforced structural steel construction for around-the-clock operation

- 42″ safety fencing with intralocking access door

- Automatic film clamp and cut device with manual override control

- Photo electronic load height sensor that detects most dark colored loads

- Variable carriage speed (0-21FPM)

- EZ-LOAD FILM-SAVR® Powered Pre-Stretch: up to 300% with minimum neck down

- Film delivery system: 1/2 HP, 90 VDC motor

- Proximity switch dancer bar control for more reliable film feed speed control and corner compensation

- Dual chain carriage lift system

- Anti-static rollers

- Corner compensation

- UL approved components

- Remote NEMA 12 electrical enclosure

Options :

- Film fault alarm that signals empty film roll, film brakes

- Roping option with special roping sequences available

- 30″ film capacity available

- Extended wrap height

- Various flow configurations available

- Material handling interlock

- Variable speed conveyors

- 90 degree discharge or entrance

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)