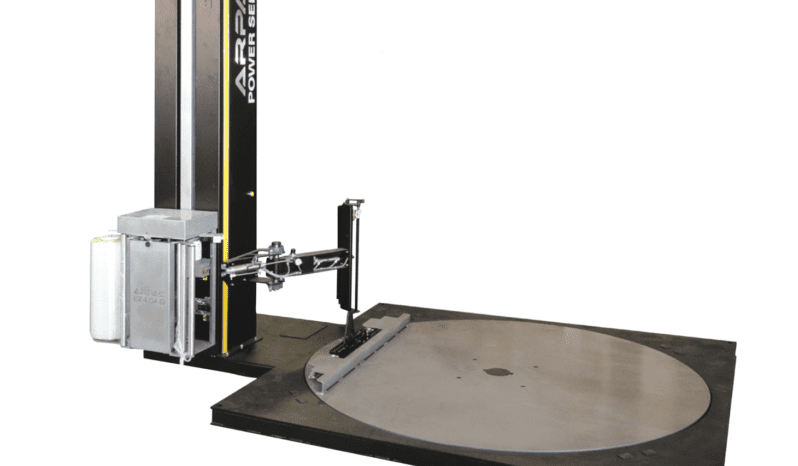

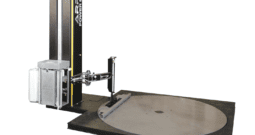

Automatic Pallet Stretch Wrapper (Low Profile)

| Condition | New |

| Category | Pallet Wrappers - Stretch Wrappers, Wrappers - Wrapping Equipment |

| Manufacturer | Arpac |

| Model | Power Series |

| Industry | Beverage, Consumer Products, Food, Nutraceutical |

| Speed | 25 to 40 Loads/Hr |

| Location | North America |

The Automatic Pallet Stretch Wrapper (Low Profile) is part of a robust line of stretch wrapping equipment designed to maximize stretch film usage while ensuring the very best load unitization. This unit is constructed with heavy-duty reinforced structural steel and finished with non-corrosive Steel-It paint, to guarantee years of reliable wrapping.

25 to 45 Loads Wrapped Per Hour (Max Load Weight 4,000lbs.)

The Automatic Pallet Stretch Wrapper (Low Profile) is an efficient stretch wrapping solution for all material handling environments. This automatic entry level turntable stretch wrapper is completely accessible to forklift operators without getting off the truck. This unit may be purchased with a built in scale feature that combines wrapping and weighing into one operation, by integrating precision controls into the turntable base.

Mode of Operation

The forklift operator sets the pallet onto the turntable. The operator then pulls the lanyard cord to begin the wrap sequence. The film is automatically attached, the pallet is wrapped, and the film is automatically cut and the tail is wiped to the pallet. Once the wrapping sequence is completed, the wrapped load is removed from the turntable platform by forklift. After the wrap zone is clear, a new load is positioned and the cycle is repeated.

- Access ramps to assist loading of pallet

- Automatic film tear device (AFTD) tears film at the end of the wrapping cycle

- Extended film towers for wrapping tall loads exceeding standard machine capability

- Cold and freezer packages available

- Adjustable manual roping guide

- Pneumatic roping device for extra load support

- 30″ film delivery system

- Other NEMA rated control enclosures available

- Top platen device to stabilize tall or light unstable loads during rotation

- 6,000 lb. and large diameter turntables available

- Integrated scale and printer available

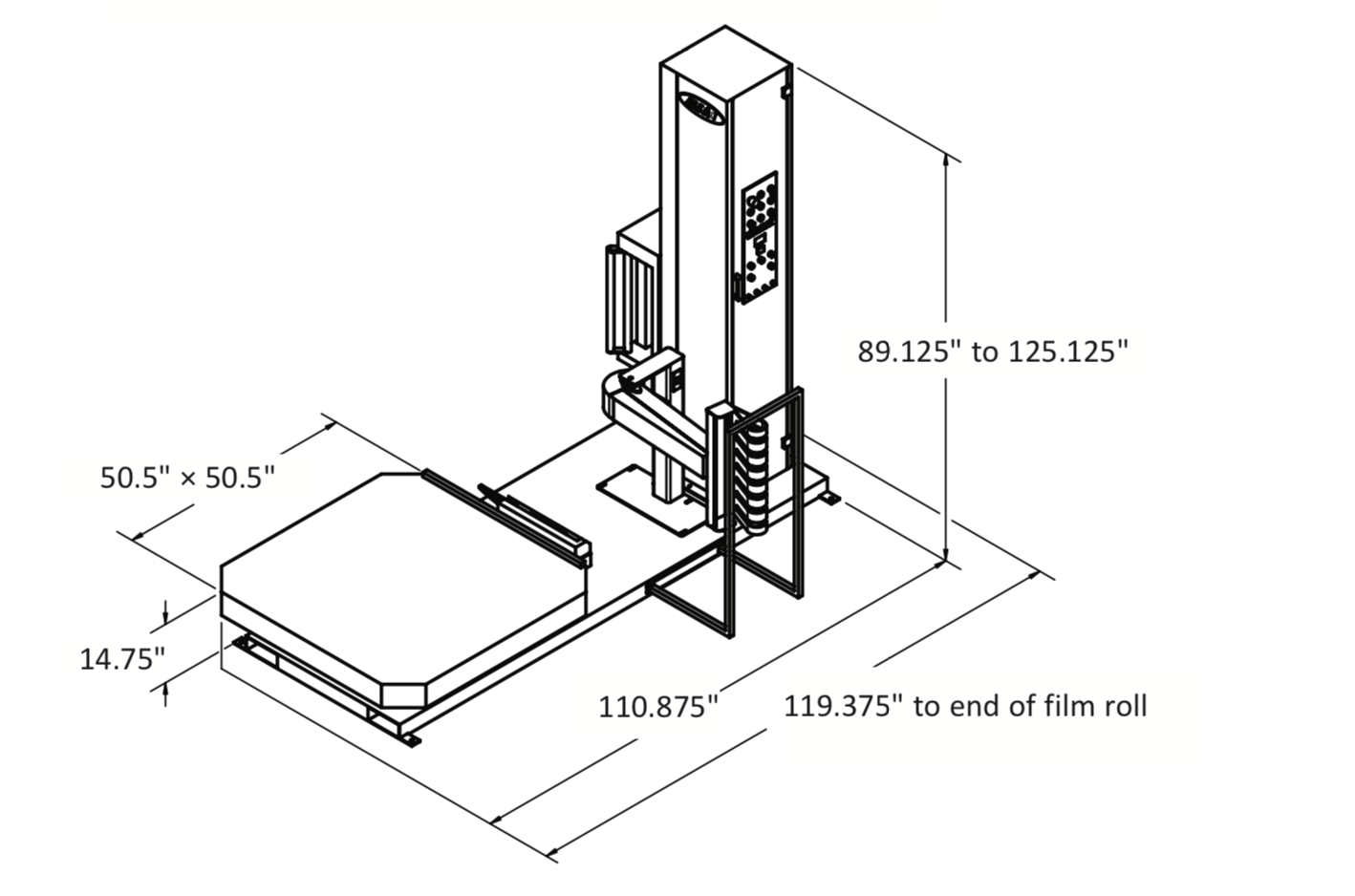

| Turntable Size – High Profile | 50" Square (standard) |

| Max. load diagonal clearance | 75" (standard turntable) |

| Max. Load Weight Capacity | 4,000 lb. (standard) |

| Turntable Rotation Speed | Up to 12 RPM |

| Variable carriage speed | Up to 21 FPM |

| Loads wrapped per Hour | 25 to 40 |

| Max Load Height – High Profile | 70" max load height (82", 94", and 106" option) |

| Electrical power requirements | 120 VAC, 1 Ph, 60 Hz, 10 A, 80 psi, 3 SCFM |

Core Features:

- Heavy-duty, welded-steel construction

- Up to 12 RPM rotating table can deliver 25–40 loads per hour

- Photo eye for automatic load height sensing

- Cycle pause feature

- Top film overwrap control feature (TOC)

- Manual jog control for turntable

- Two available wrap patterns

- Dual chain film carriage lift

- Eco-friendly, durable powder coating

- Remote lanyard for startup

- Magnetic proximity switches

- Remote lanyard to start cycle

- Adjustable top and bottom illuminated LED wrap counters from 0-7

- Magnetic proximity switches in place of mechanical limit switches

- Cycle pause feature and turntable jog control

- Top film over wrap control feature (TOC)

- Electronic film tension adjustment control on control panel

- Independent up and down film carriage controls with jog up/down switch

- Manual jog control for turntable

- Upgraded photo eye for automatic load height sensing of all color loads

- Micrologix 1200 PLC Control System using UL/CSA approved components

Options

- A variety of access ramps to assist loading of pallet

- AFTD automatic film tear device tears film at the end of the wrapping cycle

- Cold and freezer packages available

- Adjustable manual roping guide

- Pneumatic roping device for extra support of load

- 30″ film delivery system

- Other NEMA rated control enclosures available

- Top platen device to stabilize tall or light unstable loads during rotation

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)