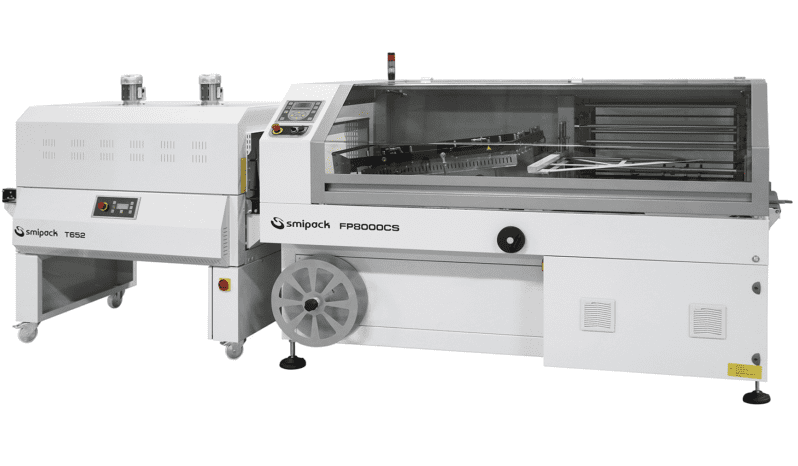

Automatic L Sealer with Shrink Tunnel

| Condition | New |

| Category | Heat Shrink Tunnels, L Sealers, Shrink Wrap Equipment, Shrink Wrappers |

| Manufacturer | SMI |

| Model | FP6000, FP6000CS, FP6000E, FP8000CS |

| Industry | Beverage, Consumer Products, Food, Nutraceutical |

| Speed | 1800 - 3600 pph |

| Location | Europe |

The Automatic L Sealer with Shrink Tunnel has an output up to 3600 packs / hour and a maximum pack height of up to 250mm. It also comes with a double hood hold-down electromagnet, that highly reduces the pressure of the operator on the sealing arm so as to ensure a better seal. Modularity and excellent price/quality ratios are the main features characterizing the Automatic L Sealer with Shrink Tunnel. All the models of this range can indeed be supplied with or without shrink tunnel.

These units have an output up to 3600 packs/hour depending on the model (see technical)

This system allows a simple and precise control of all the machine operations such as; machine status, number of packs produced by an electronic pack counter, real-time production, pack discharge speed, adjustment of the sealing temperature, work cycle scheduling, and troubleshooting. Film that can be used includes: PVC, Polyolefin, and Polythylene in compliance with CE regulations.

| Installed power | 3350 W |

| Compressed air pressure | 6 bar |

| Compressed air consumption | 0.4 Nl/p |

| Sealing bar | 640 x 510 mm |

| Maximum pack height | 150 mm |

| Speed of conveyors | 10 - 30 m/min |

| Output up to | 3000 pph |

| Maximum size of film reel | 600 - ø 350 mm |

| Machine size | 2180 x 1545 mm x h 1505-1665 mm |

| Machine net weight | 580 Kg |

| Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) | up to 30 µ |

| Power Supply | 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 3350 W |

| Compressed air pressure | 6 bar |

| Compressed air consumption | 0.4 Nl/p |

| Sealing bar | 640 x 510 mm |

| Maximum pack height | 200 mm |

| Speed of conveyors | 10 - 30 m/min |

| Output up to | 3000 pph |

| Maximum size of film reel | 600 - ø 350 mm |

| Machine size | 2180 x 1545 mm x h 1505-1665 mm |

| Machine net weight | 660 Kg |

| Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) | up to 30 µ |

| Power Supply | 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 3950 W |

| Compressed air pressure | 6 bar |

| Compressed air consumption | 0.4 Nl/p |

| Sealing bar | 840 x 710 mm |

| Maximum pack height | 250 mm |

| Speed of conveyors | 10 - 30 m/min |

| Output up to | 2700 pph |

| Maximum size of film reel | 850 - ø 350 mm |

| Machine size | 2625 x 1895 mm x h 1605-1765 mm |

| Machine net weight | 810 Kg |

| Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) | up to 30 µ |

| Power Supply | 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 3350 W |

| Sealing bar | 640 x 510 mm |

| Maximum pack height | 120 mm |

| Speed of conveyors | 19 m/min |

| Output up to | 1800 pph |

| Maximum size of film reel | 600 - ø 350 mm |

| Machine size | 2180 x 1545 mm x h 1505-1665 mm |

| Machine net weight | 580 Kg |

| Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) | up to 30 µ |

| Power Supply | 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

- FP6000

-

FP6000 - Automatic L Sealer

Installed power 3350 W Compressed air pressure 6 bar Compressed air consumption 0.4 Nl/p Sealing bar 640 x 510 mm Maximum pack height 150 mm Speed of conveyors 10 - 30 m/min Output up to 3000 pph Maximum size of film reel 600 - ø 350 mm Machine size 2180 x 1545 mm x h 1505-1665 mm Machine net weight 580 Kg Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) up to 30 µ Power Supply 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - FP6000CS

-

FP6000CS - Automatic L Sealer

Installed power 3350 W Compressed air pressure 6 bar Compressed air consumption 0.4 Nl/p Sealing bar 640 x 510 mm Maximum pack height 200 mm Speed of conveyors 10 - 30 m/min Output up to 3000 pph Maximum size of film reel 600 - ø 350 mm Machine size 2180 x 1545 mm x h 1505-1665 mm Machine net weight 660 Kg Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) up to 30 µ Power Supply 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - FP8000CS

-

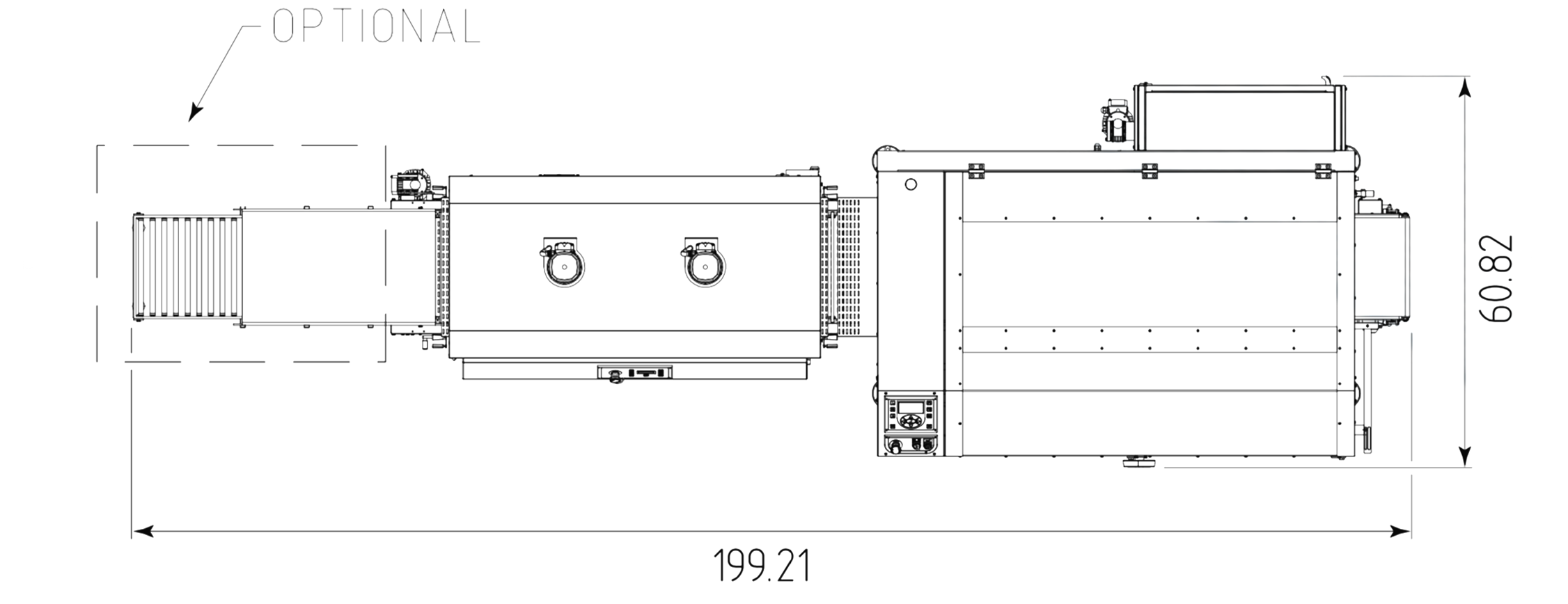

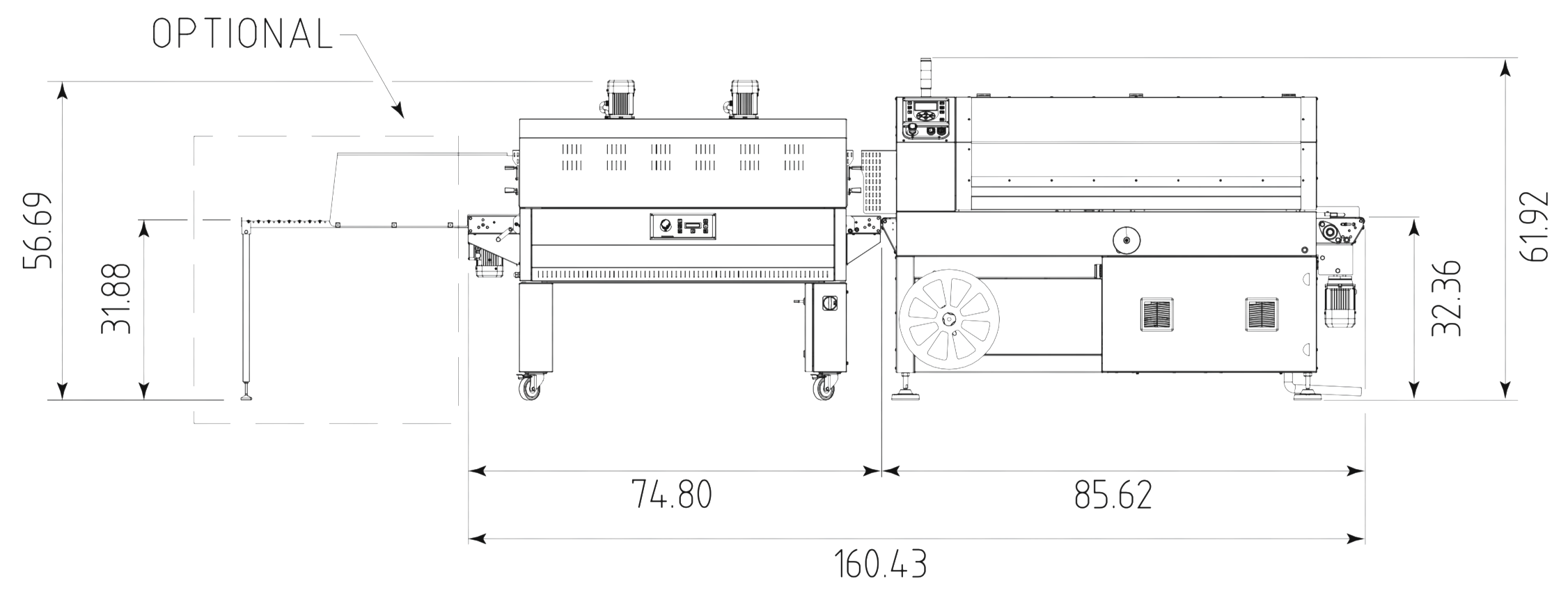

FP8000CS - Automatic L Sealer

Installed power 3950 W Compressed air pressure 6 bar Compressed air consumption 0.4 Nl/p Sealing bar 840 x 710 mm Maximum pack height 250 mm Speed of conveyors 10 - 30 m/min Output up to 2700 pph Maximum size of film reel 850 - ø 350 mm Machine size 2625 x 1895 mm x h 1605-1765 mm Machine net weight 810 Kg Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) up to 30 µ Power Supply 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - FP6000E

-

FP6000E - Automatic L Sealer

Installed power 3350 W Sealing bar 640 x 510 mm Maximum pack height 120 mm Speed of conveyors 19 m/min Output up to 1800 pph Maximum size of film reel 600 - ø 350 mm Machine size 2180 x 1545 mm x h 1505-1665 mm Machine net weight 580 Kg Usable Films: Polyolefin and Polyethylene (Polyethylene from 15 to 60 my with option sealing bar for Polyethylene) up to 30 µ Power Supply 220 - 240 / 380 - 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz

| Installed power | 8000 W |

| Maximum pack height | 230 mm |

| Speed of conveyors | 3 - 18 m/min |

| Machine size | 1310 x 835 mm x h 1440 mm |

| Machine net weight | 187 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 50 µ |

| Power Supply | 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 12750 W |

| Maximum pack height | 230 mm |

| Speed of conveyors | 6 - 37 m/min |

| Machine size | 1900 x 835 mm x h 1440 mm |

| Machine net weight | 300 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 80 µ |

| Power Supply | 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 9500 W |

| Maximum pack height | 300 mm |

| Speed of conveyors | 2 - 12 m/min |

| Machine size | 1380 x 1045 mm x h 1565 mm |

| Machine net weight | 241 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 50 µ |

| Power Supply | 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

| Installed power | 15800 W |

| Maximum pack height | 300 mm |

| Speed of conveyors | 3 - 18 m/min |

| Machine size | 1910 x 1045 mm x h 1565 mm |

| Machine net weight | 380 Kg |

| Usable Films: Pvc, Polyolefins and Polyethylene | up to 80 µ |

| Power Supply | 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz |

- T450

-

T450 - Tunnel for modular L Sealing

Installed power 8000 W Maximum pack height 230 mm Speed of conveyors 3 - 18 m/min Machine size 1310 x 835 mm x h 1440 mm Machine net weight 187 Kg Usable Films: Pvc, Polyolefins and Polyethylene up to 50 µ Power Supply 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - T452

-

T452 - Tunnel for modular L Sealing

Installed power 12750 W Maximum pack height 230 mm Speed of conveyors 6 - 37 m/min Machine size 1900 x 835 mm x h 1440 mm Machine net weight 300 Kg Usable Films: Pvc, Polyolefins and Polyethylene up to 80 µ Power Supply 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - T650

-

T650 - Tunnel for modular L Sealing

Installed power 9500 W Maximum pack height 300 mm Speed of conveyors 2 - 12 m/min Machine size 1380 x 1045 mm x h 1565 mm Machine net weight 241 Kg Usable Films: Pvc, Polyolefins and Polyethylene up to 50 µ Power Supply 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz - T652

-

T652 - Tunnel for modular L Sealing

Installed power 15800 W Maximum pack height 300 mm Speed of conveyors 3 - 18 m/min Machine size 1910 x 1045 mm x h 1565 mm Machine net weight 380 Kg Usable Films: Pvc, Polyolefins and Polyethylene up to 80 µ Power Supply 220 - 240 / 380 – 415 V | 3PH + PE / 3PH + N + PE | 50/60 Hz

- Automatic L-sealer with shrink tunnel

- Motorized sealing bar controlled by inverter and encoder

- Machine manufactured in stainless steel AISI 304

- Alimentary belts with FDA, UE, USDA conformities

- Conveyor closing system included

- Motorized center seal system

- PTFE-coated sealing blade

- Emergency button

- Safety device

- Continuous cycle sealing

- possibility of storing up to 20 different operation programs

- automatic control of the sealing bar height

- double adjustment of the sealing blade temperature, both lengthways and broadways

- sealing time adjustment

- possibility of packing single packs or multipacks

- speed of conveyorselectronically adjustable from the control panel

- process statistics

- Reduced power consumption

- Compliance with CE regulations

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)