Ronchi 40 Valve Mass Flow Hot Fill Monoblock Filler

| Condition | |

| Category | Fillers - Filling Equipment, Hot Fill Fillers, Monobloc Fillers, Rotary Fillers |

| Manufacturer | Ronchi |

| Model | Exacta-R |

| Industry | Beverage, Chemical, Consumer Products, Food, Nutraceutical, Pharmaceutical |

| Location | North America |

| Stock Number | 0216-200407 |

High filling accuracy: σ= 0.2% 48oz @ 240 BPM, 64oz @240 BPM, 96 oz @ 180 BPM, 128 oz @ 120 BPM

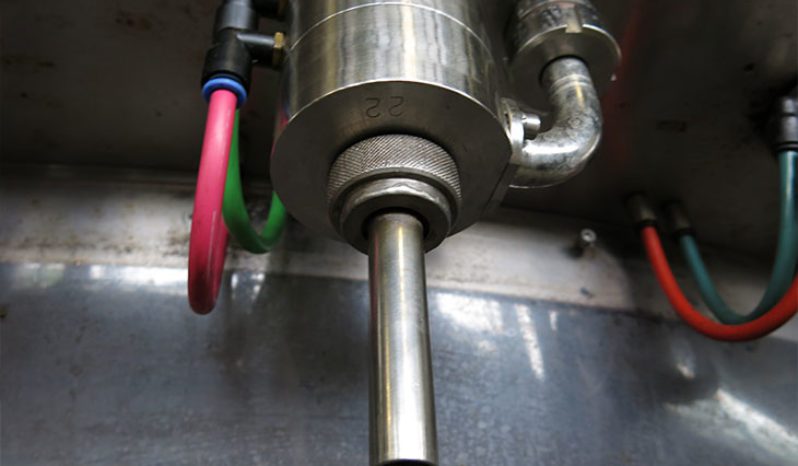

| Filling Valves | 40 Valves (9.25" centers) |

| Capping Heads | 20 Heads (10" centers) |

| Filling Accuracy | 0.2% |

| Automatic CIP/SIP temp | up to 266°F (130°C) |

| Bottle Height Range | 8-1/2" to 10-1/2" |

| Previous Use | 48oz to 128oz Round and Rectangle HDPE Bottles |

| Filler Speeds | 48oz @ 240 BPM, 64oz @240 BPM, 96 oz @ 180 BPM, 128 oz @ 120 BPM |

| Overall Dimensions | 18’ L x 13’ W x 9-1/2’ H |

Ronchi 40 Valve Mass Flow Hot Fill Monoblock Filler

Do you have a Ronchi 40 Valve Mass Flow Hot Fill Monoblock Filler or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Ronchi 40 Valve Mass Flow Hot Fill Monoblock Filler to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)