Automatic High Level Depalletizer

| Condition | New |

| Category | Automatic Depalletizers, Depalletizers, High Level Depalletizers |

| Manufacturer | GRX |

| Industry | Beverage, Brewery, Distillery, Food, Winery |

| Location | North America |

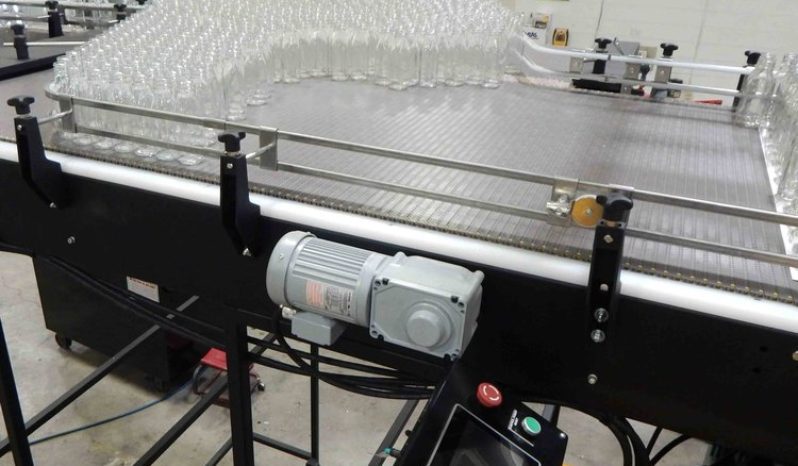

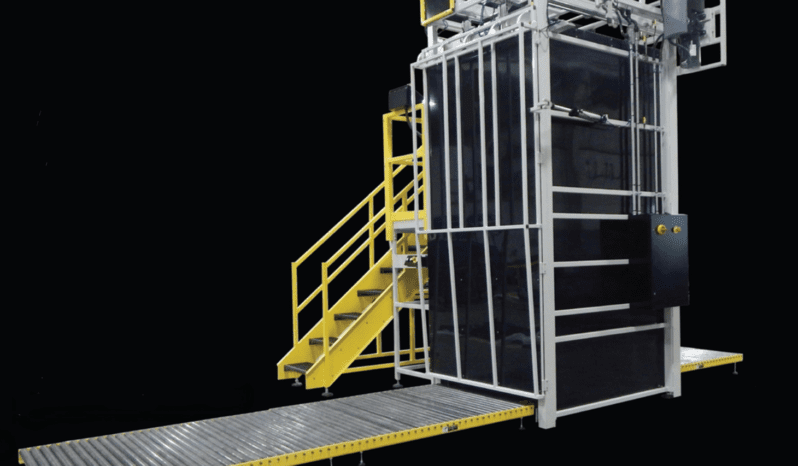

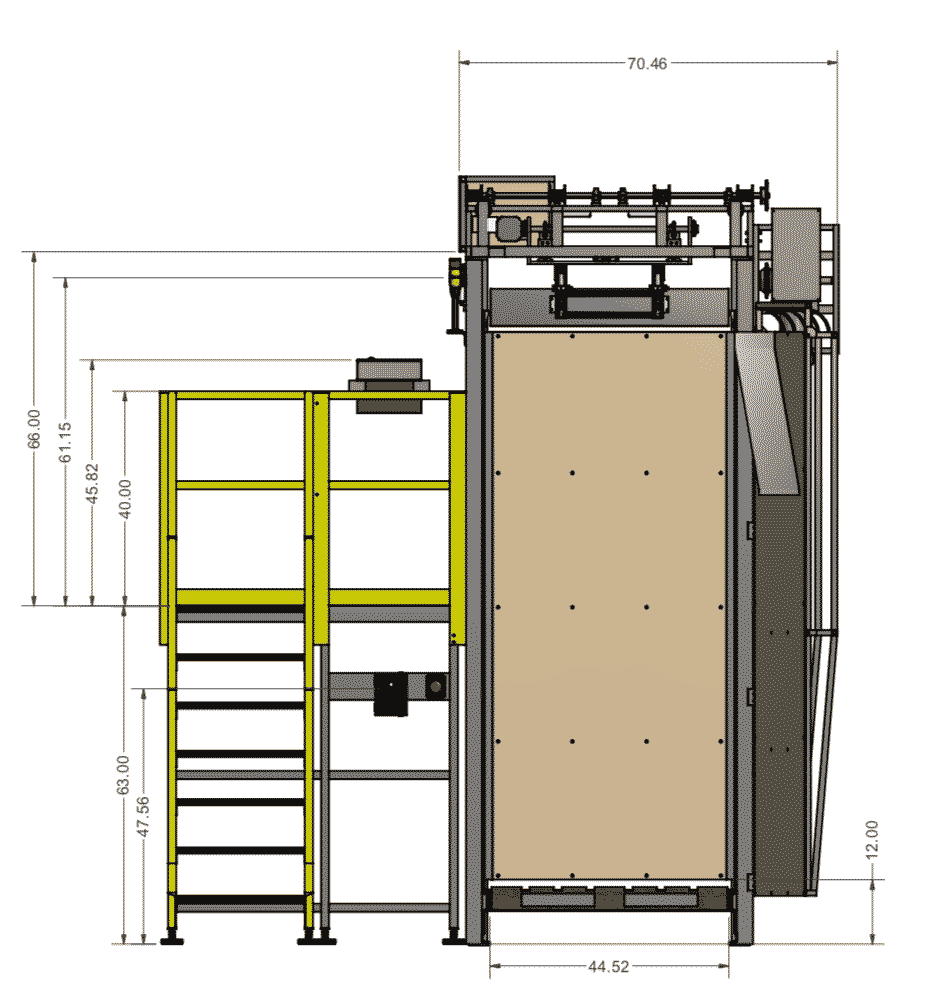

The Automatic High Level Depalletizer automatically unloads full pallets of aluminum cans or plastics containers. Unit features user friendly push button controls and electrically driven lift and sweep assembly motors that allow for smooth, reliable, and continuous operation.

Depalletizer design supports flexible configurations, allowing it to be tailored to customer-specific requirements.

These depalletizers are robustly constructed, utilize quality components, and are designed with easy operation, reliable performance, and a compact footprint in mind. The operator loads the pallet and closes the interlocked safety door. The stack is automatically raised and swept onto the accumulation table. Automatic slip sheet removal lowers the slip sheet to floor level for easy removal. Once the pallet is fully unloaded, the empty pallet is removed by the operator and the process is repeated.

- Slip sheet removal system

- Electrical break system

- HMI push button controls

- Unit integrated lift carriage

- Black H.D.P.E lexan side panels

- Power-coated Steel Construction

- Low volume air consumption

- Electrical Break System

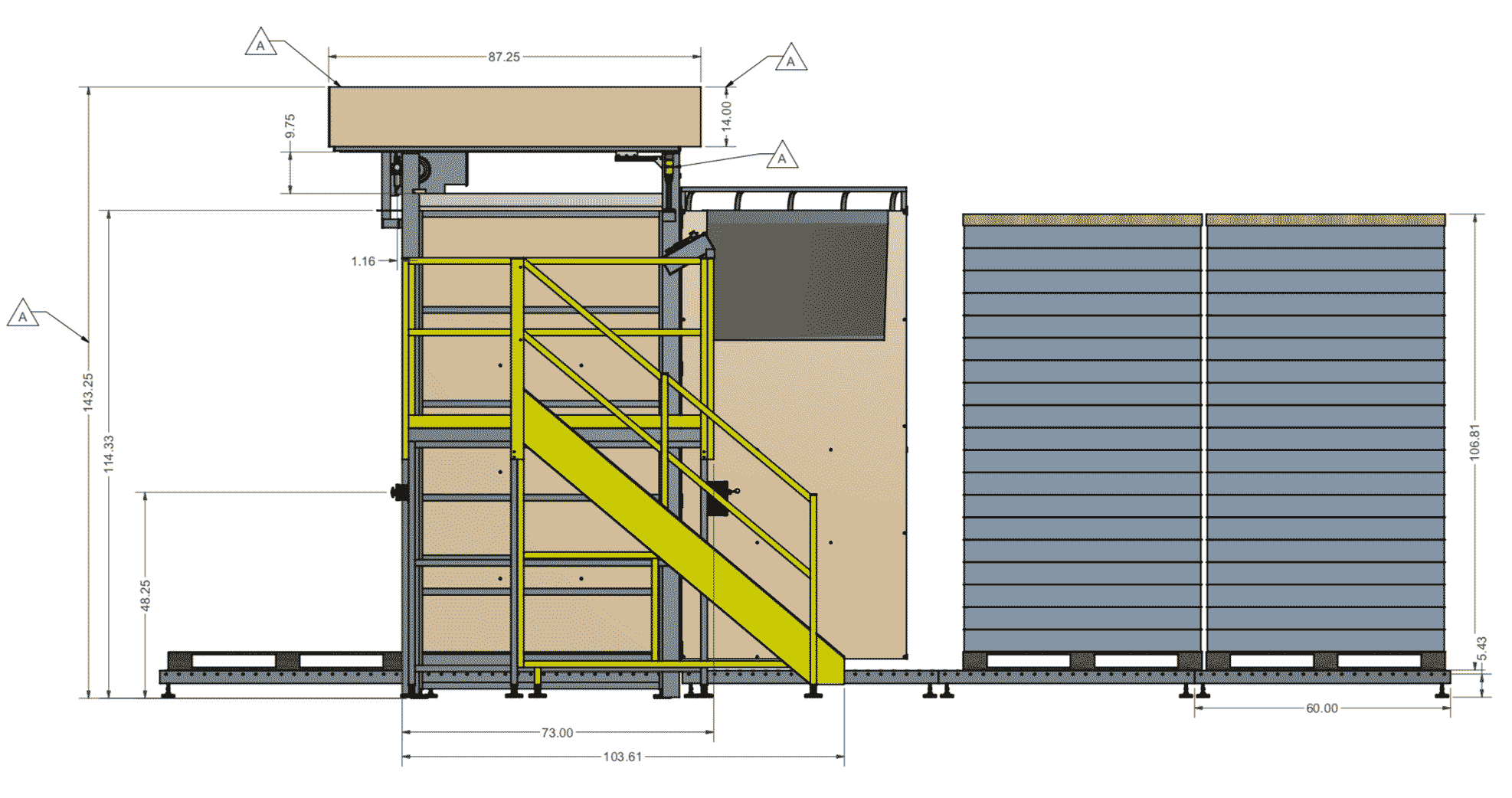

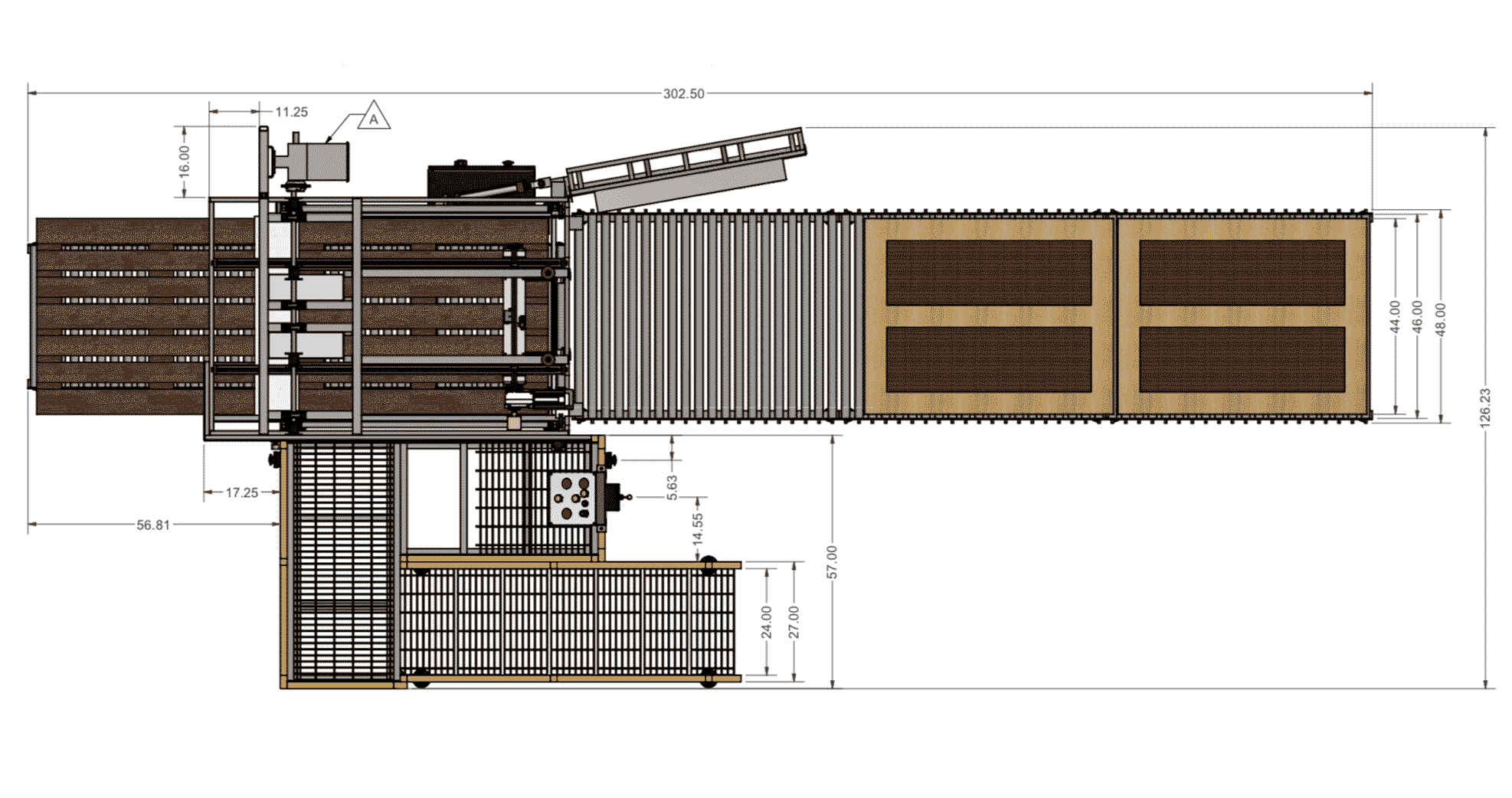

| Footprint | 55"L x 72"W x 146"H |

| USA | 115 VAC / 60 Hz |

| Pallet Sizes | 44x56 inch, 40x48 inch, custom |

Core Features:

- In-unit integrated lifting carriage

- Interlocked safety door at pallet infeed

- Electrically driven lift and sweep assembly motors

- Black H.D.P.E lean side panels

- Electrical break system on lift mechanism

- Automatic slip sheet removal system

- Low volume air consumption

- User friendly HMI push button controls

- Powder-coated steel construction

Standard Configurations:

- 500 lb to 5,000 lb lifting capability

- Standard pallet sizes 44×56 inch, 40×48 inch, or custom

- Heavy duty carbon steel frame or stainless steel construction

- Fiberboard, Corrugated fiberboard, plastic, or inverted tray slip sheet removal systems

- May be configured to accommodate a wide variety of discharge speeds

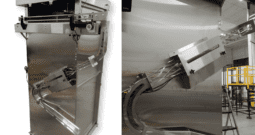

Discharge / Decline Options:

- Side Discharge Conveyor

- Straight Vertical Chute

- Straight Vertical Chute

- Mass Accumulation Table

- Side Grip Decline

- Hi-Speed Single Filer

- Bottle chute

CUSTOM DEPALLETIZER REQUEST

Do you have a Automatic High Level Depalletizer or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Automatic High Level Depalletizer to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)