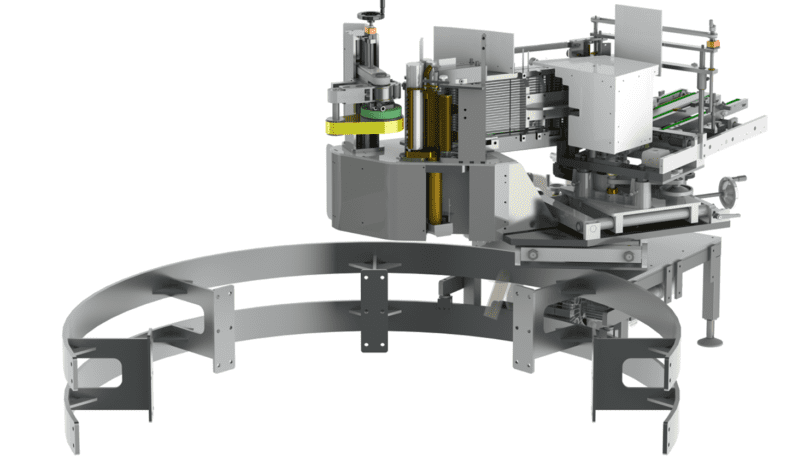

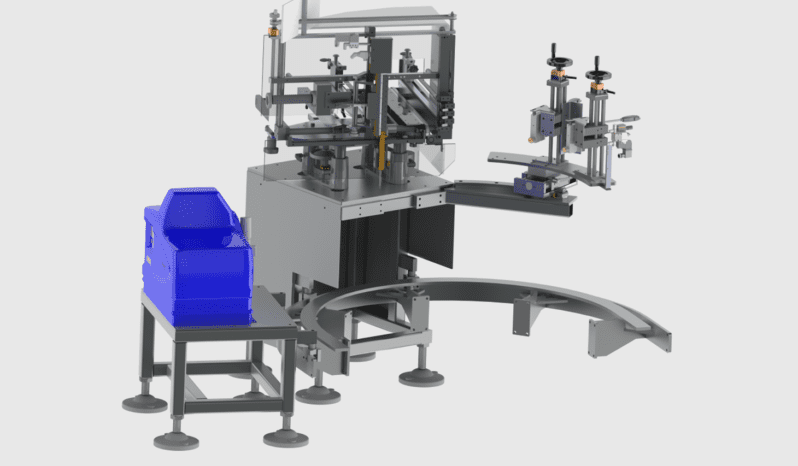

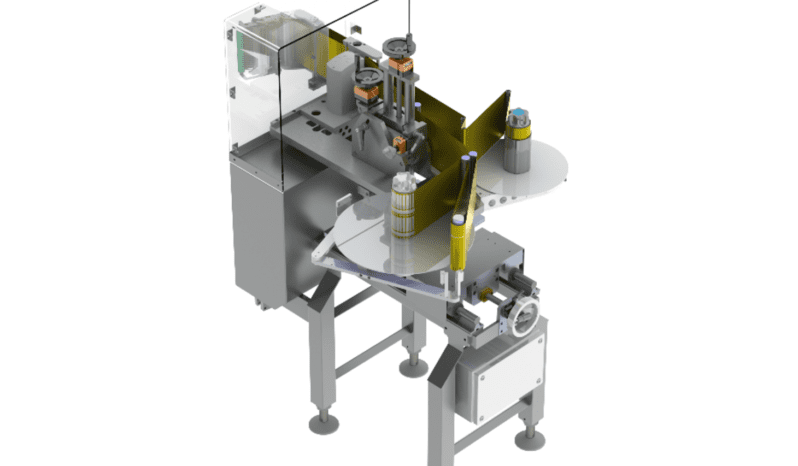

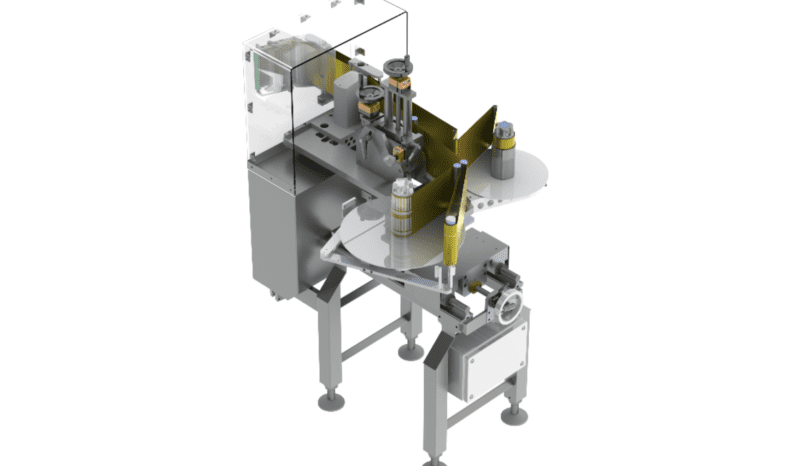

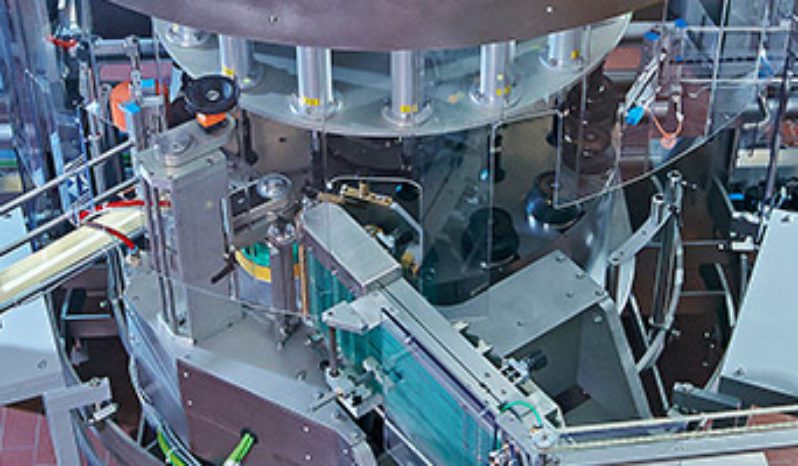

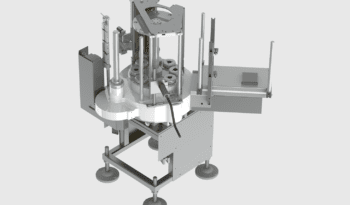

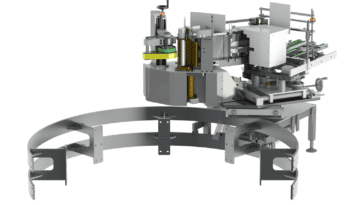

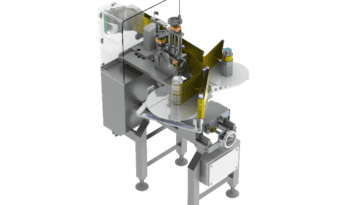

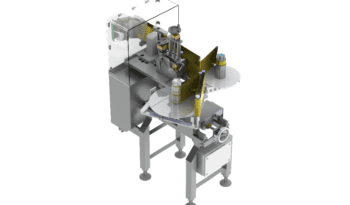

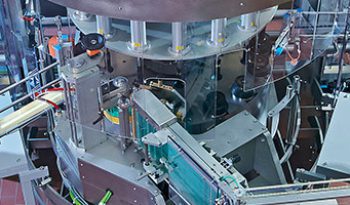

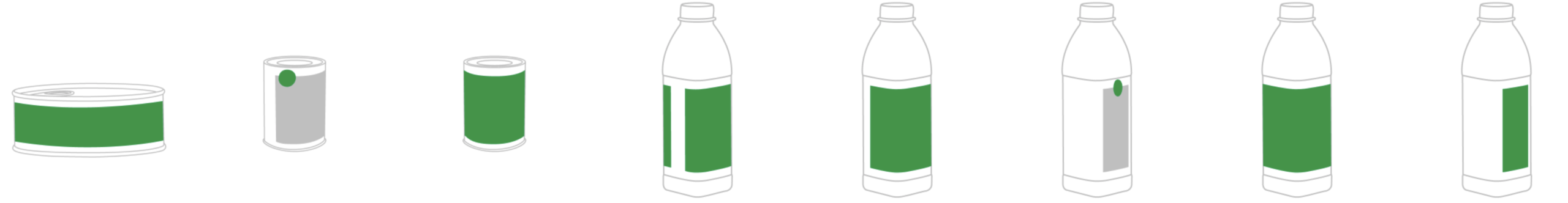

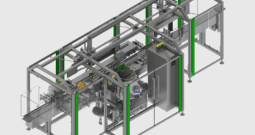

The new innovative Multi Purpose Combination Labeler fulfills customers‘ individual requirements: Every label and every container can be processed using the requested labelling technology. The rotary labellers are working with hotmelt, wet glue or self-adhesive labelling systems using the pre-installed labelling units as per customers‘ request. This allround system is ready for immediate use and extensive conversion works are therefore no longer necessary. Cold glue stations typically rely on direct label transfer method which eliminates glue pallets and associated wear and change parts. Hot melt stations use adhesive saving spray glue system. And the servo pressure sensitive heads are of the highest caliber.

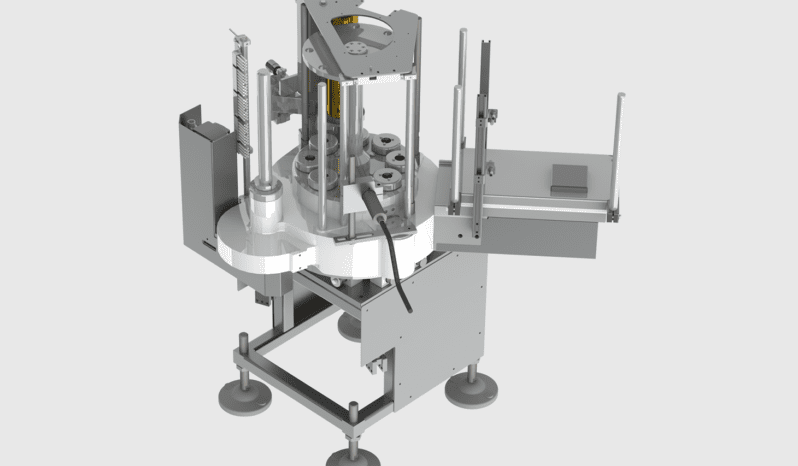

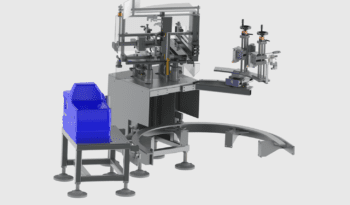

Rotary labeler with up to four labeling stations encompassing hot melt, wet glue, and pressure sensitive formats for nearly any container and label shape.

For almost limitless flexibility LANGGUTH offers its moduLAN® rotary labeler with up to four labeling stations encompassing hot melt, wet glue, and pressure sensitive formats for nearly any container and label shape. Customers appreciate the opportunity to select a combination of label types using single modules, multiple modules, or combination modules. The moduLAN® is offered in three different speed ranges.