Production Ready Crown 40 Valve Can Filler with Angelus 61h Seamer

| Condition | Production Ready |

| Category | Beverage Fillers, Can Fillers, Can Seamers - Closers, Fillers - Filling Equipment |

| Manufacturer | Angelus, Bevcorp, Crown |

| Model | 40 Valve, 61h |

| Year | 2018 |

| Industry | Beverage |

| Speed | 575 CPM |

| Location | North America |

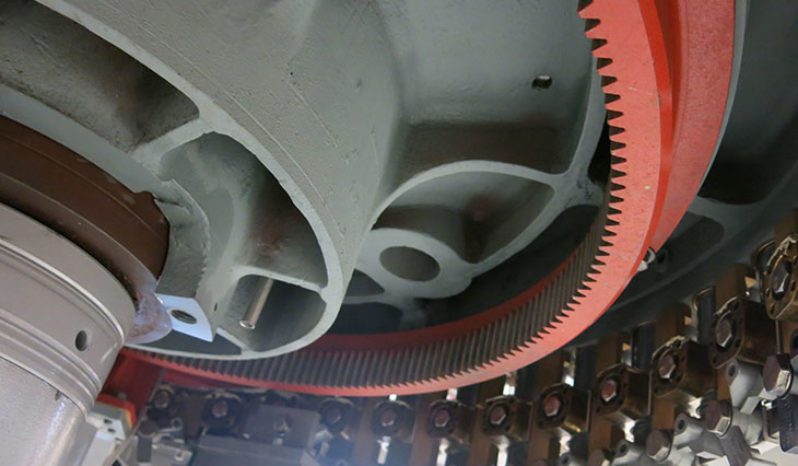

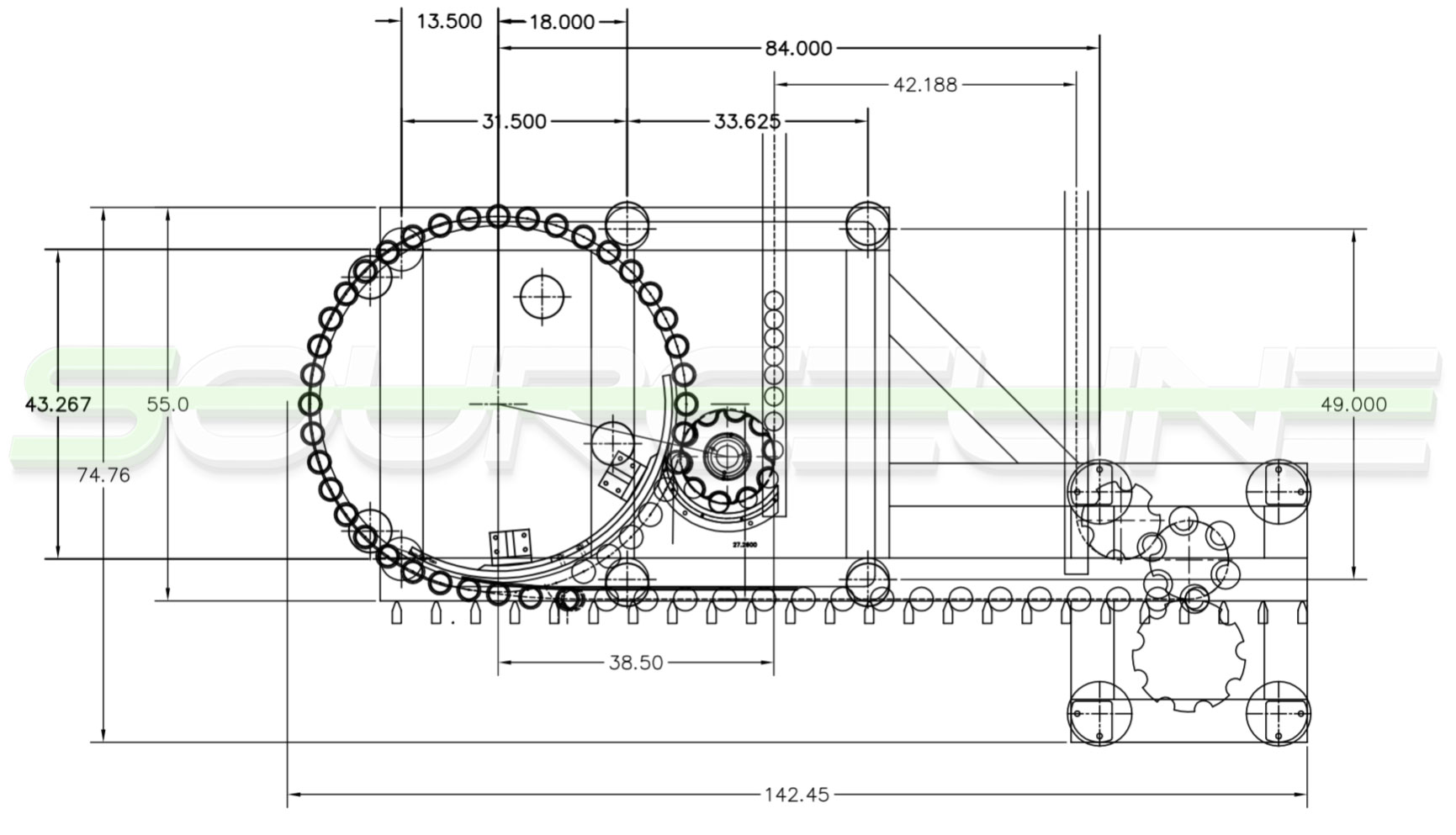

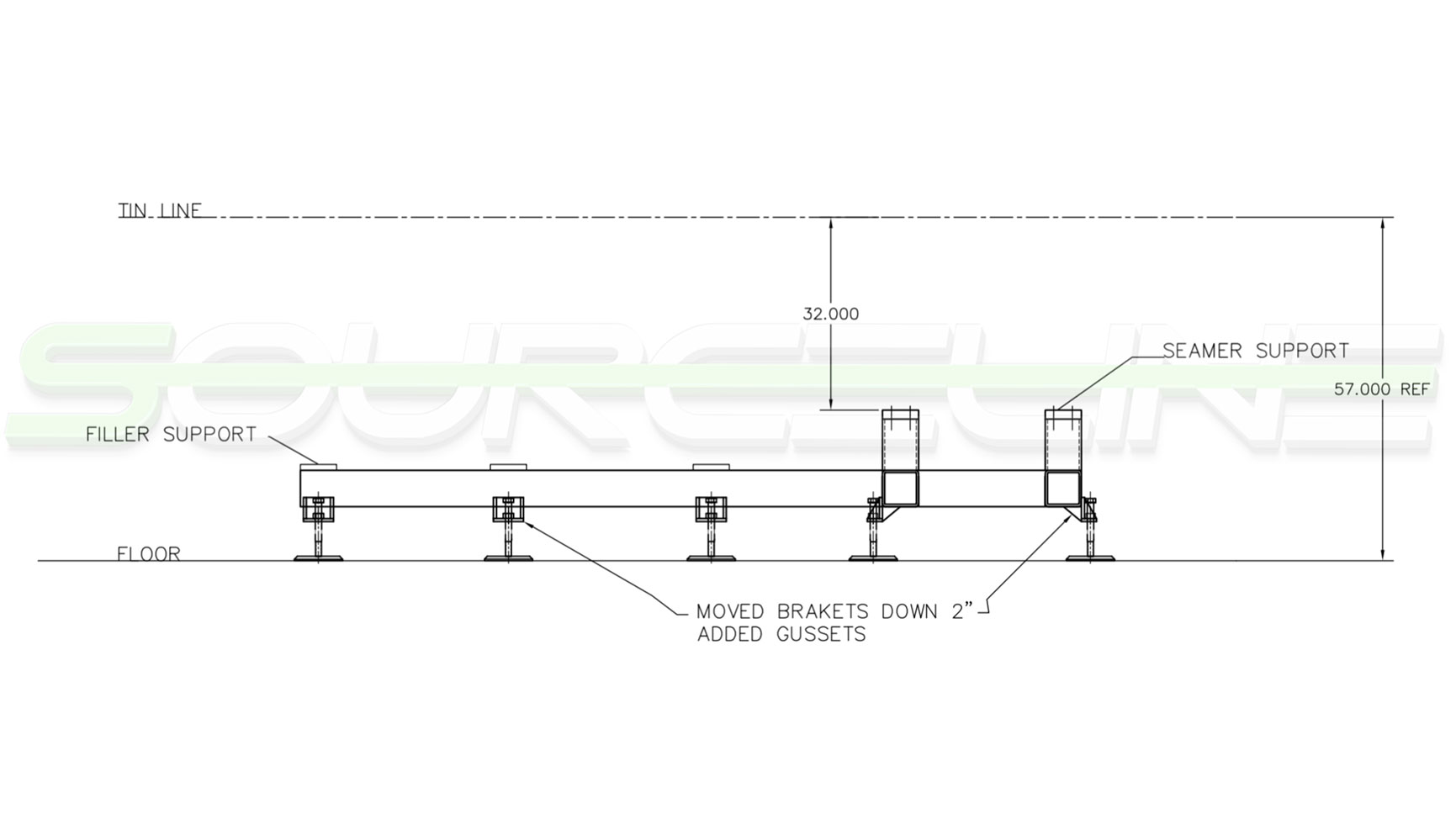

This Production Ready Crown 40 Valve Can Filler with Angelus 61h Seamer is painted cast steel and includes: a NEW common filler/seamer base, Lift cylinder upholding mechanism, main drive gearbox, roller stanchion bearings and couplings are rebuilt or replaced. Stainless steel trip support ring with rebuilt opener and closer and new snift cam and brackets. Infeed spider drive gearbox, worm drive jackshaft, worm drive gearing, worm drive jack shaft brackets, and worm drive gearbox are rebuilt or replaced. All rubber goods, cam shaft housings, cam shafts, actuating levers and actuating lever shear washers are also replaced or rebuilt. The Production Ready Filler also features rebuilt tip-less can filling valves.

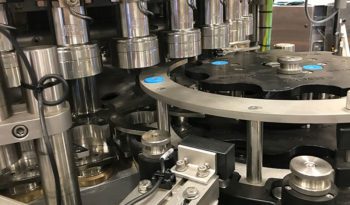

Unit consists of chucks and rolls for 200 and 202 end, UCG, filler connection and body handling parts for 200/202 x 503 (250ml) and 202/207.5 x 510 (355ml)

The overhauled Angelus 61h Can Seamer has been completely disassembled ; all existing paint is stripped from the castings. Castings were sandblasted and prepped for Epoxy Paint. All internal and external castings were inspected to ensure they meet OEM specifications. Seamer includes handling parts for 202/211 can and comes with chucks and rolls for 200 and 202 end, UCG, filler connection and body handling parts for 200/202 x 503 (250ml) and 202/207.5 x 510 (355ml). All Crown can fillers for soft drinks are recognized world-wide for their durability, reliability and consistently high output at low operating cost. Crown can fillers are designed and built to be rugged and cost effective.

- Maximum Output

- Fail-safe Lubrication

- Control Console

- Automatic Oil Lubrication System

- Maximum Lateral Stability

- Minimum Friction

| Manufacturer | Crown |

| 40 Valve | Over 575 cpm (12oz U.S.) |

| Filling Valves | Rebuilt Crown Tipless (40) |

| Actuating Cam Assy | OEM Style |

| Centering Bells | (200/202 QC Series) (202/207.5 QC Series) |

| Can Guides / Accel. Fingers | (200 Dia. QC) (202 Dia QC) |

Contains the following major components

- Rebuilt Gearboxes

- Rebuilt Pull-Down Cam

- Ring Gear

- Bowl Only CIP rotary / return system

- SS Product Bowl

- Bowl Baffle

- Can Platforms

- Guide Rails

- Rebuilt Trip Support arms

- Cam Housings

- Lift Cylinders / Ends / Brushings

- Basic Lube / Air System

- Can Sensor & Opener

- High Volume CO2 Float

- NEW Adcor Tipless Filling Valves

- Manual elevating system with base filler

- Infeed Control Parts

- Platforms

- Guide Rails

- Base Conversion

- Can Centering Guids

- Solid Can Stanchions

| Manufacturer | Angelus |

| 61h | 600 cpm (dia 50.8 - 108mm) (ht 41.3 - 203.2mm) |

| 61h Seamer Change Parts | (202/211) (202/207.5 x 510) (200/202 x 503) |

Contains the following major components

- New Bearings and Seals

- New Electrical Brake Assy

- G16 Gearing

- New Manzel drip oiler

- CO2 Gassing Panel

- Can Feed Extension

- Discharge Conveyor

- Filler Drive w/ In-Motion Timer

- 80 Series Slow Rise Cam

- Feed Chain Assembly

Features

- Built for long service life

- Designed for low maintenance costs

- Smoothest operation is assured

- Automatic shutoff cuts product loss

- High flow-rate filling valves

- NEW SS common filler / seamer base

- OEM style Trip Support Arms

- Refurbished Can Valves with QC mounting adaptors and bells

- Rebuilt Pull Down Cam

- High Volume CO2 Float

Options

- Mechanical Guarding

- Premium Lubrication Control System

- Premium Controls Package

- Custom Change Parts

CUSTOM BEVERAGE FILLER / CLOSURE REQUEST

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)