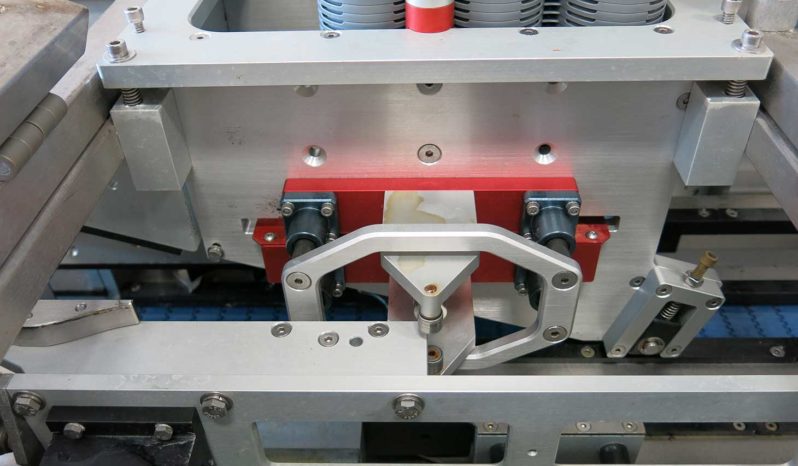

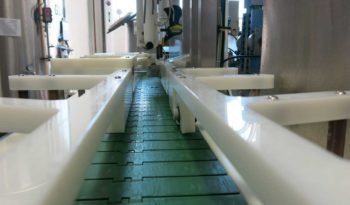

The Used Wild Goose 40CPM Automated Canning Line has a pallet width can entrance to transport system for introduction of cans from slip sheet. Wash down compatible conveyor system for transport of cans throughout the system with continuous lubrication idler system and under belt drip tray. Pre-fill CO2 purge. Next Generation filler with accompanying software to make volume, foam, and pour adjustments and retrieve dispensing metrics. Necessary tools and training to make flow adjustments. Automated lid placement. Lid sensing pre-seam to allow operator intervention prior to introduction of can into seamer. Integrated cam driven seamer including industry standard rollers and sealers for specified cans and polycarbonate safety/splash guard. 100% pneumatic componentry except for seamer and conveyor motors. Wash down compatible sensors throughout. Wash down compatible enclosures throughout. Easy Access User interface with touch panel interface and intuitive actuation of all crucial movements. Compact footprint design to fit on site space requirements. Modular Design allowing the retrofit of additional fill heads and seamer to increase capacity as needed. Quad-fill two tower configuration.

The line is capable of running 38 – 42 Cans Per Minute.

Winch driven pallet lift and pallet housing to lift pallet and sweep cans onto conveyor system with operator assistance. Gravity fed twist pre- rinse module to provide an initial inverted wash of the cans prior to introduction into the main conveyor. Option for either air blast or water wash for cleansing cans. Specific to a preferred can size. Additional belts for higher throughput. Pneumatic sweep arm to facilitate off-loading of cans onto conveyor.