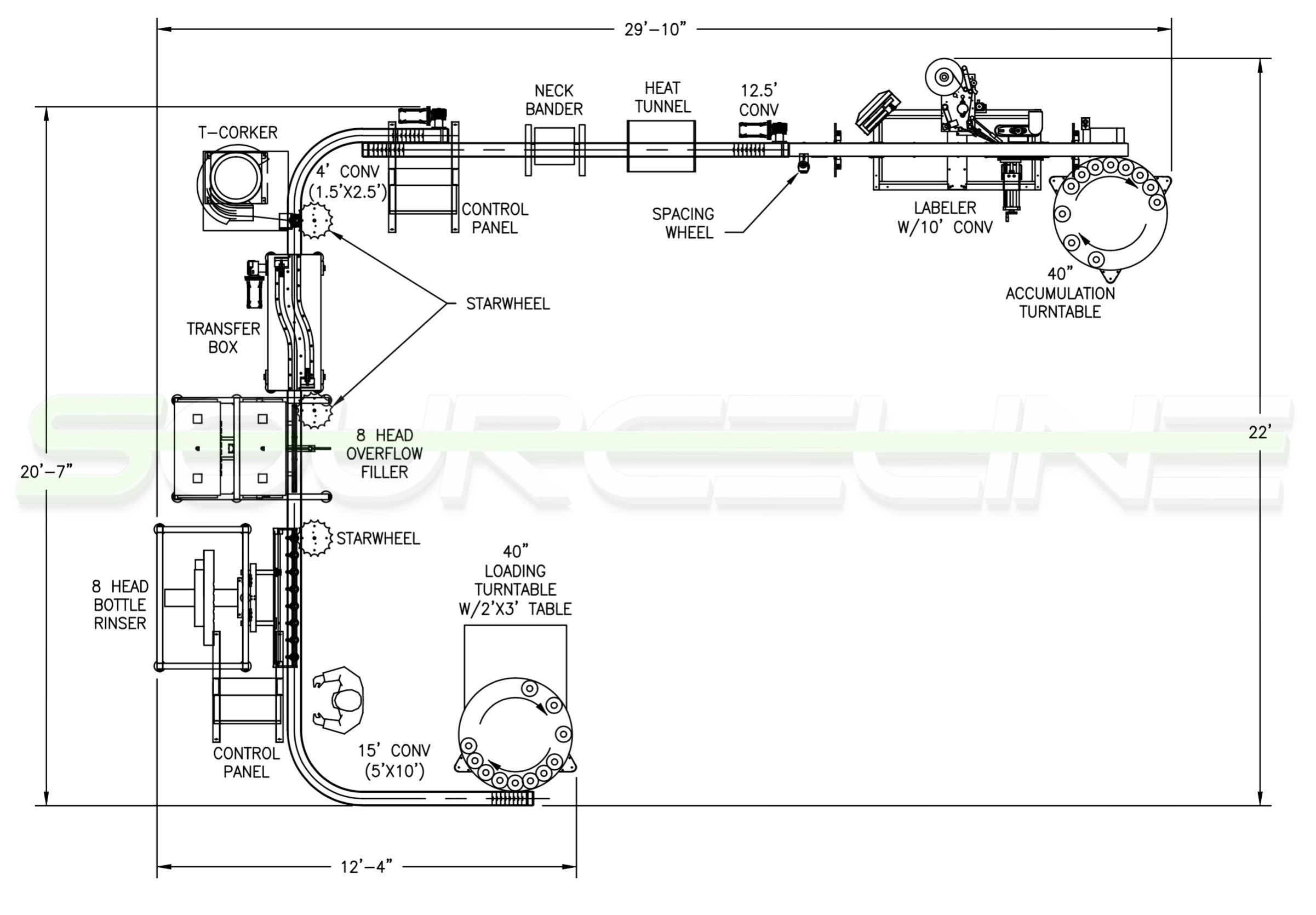

Distilled Spirits & Wine Bottling Line

The Distilled Spirits & Wine Bottling Line is a quality filling system for bottle filling in the distilled products, craft distilling and micro distilling industries.

This line can be upgraded and customized to meet any requirement the customer may have

- Tool-less Change Over

- Variable Speed Control

- 24-7 Support

- Stainless Steel Construction

- User-Friendly Controls

- Deep-vented overflow nozzles

40” Loading Turntable

304 stainless steel top. 304 stainless steel frame construction. Standard line height 32?-38”. Clockwise or counterclockwise rotation. Double rail system with HDPE bottle contact surface. Tool-less adjustable rail brackets. Half-moon loading dead plate to assist bottle loading, 2? x 3’. Variable speed control box mounted on machine cabinet. 115/230Volt/1f/50-60Hz.

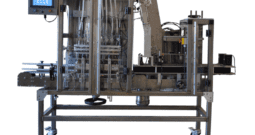

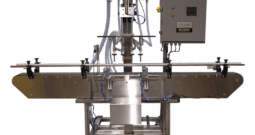

8 Head Automatic Bottle Air Rinsing System

Heavy-duty 304 stainless steel frame. 316 stainless steel 5/8? deep-vented overflow nozzles. Stainless steel gravity reservoir feeds product to fill heads. Stainless steel overflow reservoir receives overflow product and pumps it back to the gravity tank. In tank product level-sensing float system. Stainless steel centrifugal recirculating pump to feed product back to gravity tank. Flexible braided PVC tubing. User-friendly Allen Bradley / Micrologix 1200 controls with color touch screen and automatic set-up capabilities. Manual height jack. Automatic drip tray protects bottles from potential drips. Starwheel indexing includes one double-stacked star wheel. Photo sensor/counter system to ensure containers are in place prior to filling. Container neck locators for proper bottle alignment under fill heads. Motor starter and supply pump not included. 115V/1f/50-60Hz, compressed clean and dry air at 80-100PSI.

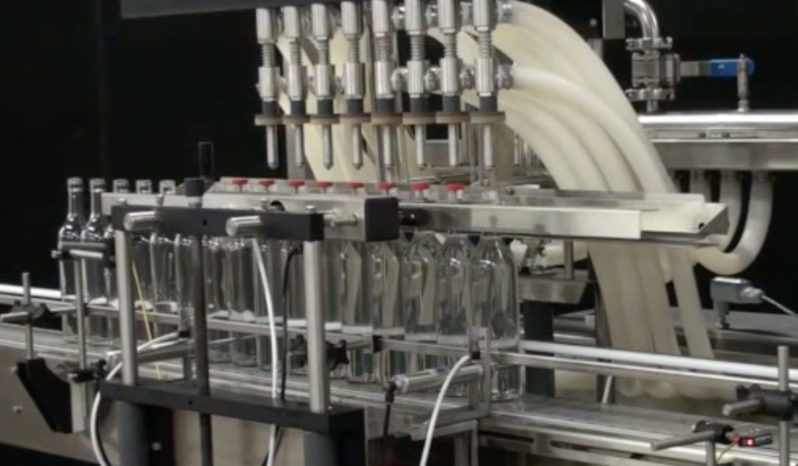

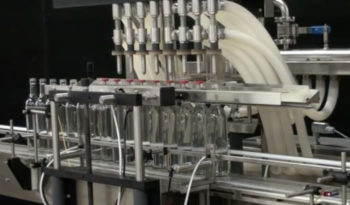

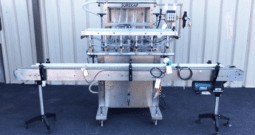

8 Head Automatic Gravity Overflow Filler

Heavy-duty 304 stainless steel frame. 316 stainless steel 5/8? deep-vented overflow nozzles. Stainless steel gravity reservoir feeds product to fill heads. Stainless steel overflow reservoir receives overflow product and pumps it back to the gravity tank. In tank product level-sensing float system. Stainless steel centrifugal recirculating pump to feed product back to gravity tank. Flexible braided PVC tubing. User-friendly Allen Bradley / Micrologix 1200 controls with color touch screen and automatic set-up capabilities. Manual height jack. Automatic drip tray protects bottles from potential drips. Starwheel indexing includes one double-stacked star wheel. Photo sensor/counter system to ensure containers are in place prior to filling. Container neck locators for proper bottle alignment under fill heads. Motor starter and supply pump not included. 115V/1f/50-60Hz, compressed clean and dry air at 80-100PSI.

Curved Rinser/Filler Conveyor

5? idle section, (1) 90 degree section, 10? drive section. 304 stainless steel shell construction. 4.5? wide Delrin chain belt. Standard line height range 32-38”. Double stainless steel rail system with HDPE wear strip. Tool-less adjustable rail brackets. “S”- shaped transfer (drive section). Standard 90Volt DC 1/2HP motor. Variable speed controls. 115/230Volt/1?/50-60Hz.

1 Head Automatic Corking Unit

Stainless steel feeder bowl. Adjustable painted steel bowl cart. Crank height adjustable for cap chute alignment. Full chute bowl pause eye. Automatic starwheel indexing with 1 double-stacked star wheel. Adjustable delivery chute with V-block centering guide and pneumatic cylinder to press cork into container. Variable speed bowl drive base and controller. Not rated hazardous location construction.

Curved Corking Conveyor

1.5? idle section, (1) 90 degree section, 2.5? drive section. 304 stainless steel shell construction. 4.5? wide Delrin chain belt. Standard line height range 32-38”. Double stainless steel rail system with HDPE wear strip. Tool-less adjustable rail brackets. “S”- shaped transfer (idle section). Standard 90Volt DC 1/2HP motor. Variable speed controls. 115/230Volt/1 ? /50-60Hz.

Shrink Band Machine

The Autocapsealer system will utilize roll stock heat shrinkable PVC tubing, automatically cut the tubing to the desired length, and apply the cut band around the cap and body of your containers. Includes: Material guide to dispense one size diameter tubing, Photo electric eye for container detection, System to space containers, Operational line speed to be up to 100 products per minute, Direction of travel is left to right, Maximum cut length for the system is 78mm (3”), Maximum lay flat for this system is 90mm, Cap sizes from 18mm to 48mm.

12.5’ Neck Banding Conveyor

304 stainless steel shell construction. 4.5? wide Delrin chain belt. Standard line height range 32-38”. Double stainless steel rail system with HDPE wear strip. Tool-less adjustable rail brackets. Standard 90Volt DC 1/2HP motor. Variable speed controls. 115/230Volt/1 ? / 50-60Hz.

Open Style Labeling System

Stainless steel open style base module. Easy to use swivel touch panel control cabinet (left hand mounted). Base module houses all electrical/electronics components. Side mounted label head module with label peel plate assembly, product sensor, standard label gap sensor, 12” diameter label spool, stepper motor driven backing paper rewind (Re-wind label media speed up to 1,200 inches/min), mounting base with four axis plus angular range of movement, tool-less positional adjustment & quick reference gradient rule set-up shaft.

Wrap module with synchronized stepper motor drive and tool-less adjustment for height and backing pad with gradient rule quick reference up to 5.5?H x 19? long label. Product spacer wheel with synchronized stepper motor drive and tool-less adjustment. 10 ft long x 4.5” wide standard product conveyor with durable table top chain belt, synchronized, stepper motor driven and tool-less adjustable twin bar guide rails and emergency stop controls. Adjustable height from 33” – 41”. 50PSI clean dry source/ regulated on labeler. 110VAC/ 1f/ 20 amps; 50/60Hz, 4A fuse rating OR 220VAC/ 1f/ 20 amps; 50/60Hz, 2.5A fuse rating.

40” Accumulation Turntable

304 stainless steel top. 304 stainless steel frame construction. Standard line height 32?-38”. Clockwise or counterclockwise rotation. Double rail system with HDPE bottle contact surface. Tool-less adjustable rail brackets. Variable speed control box mounted on machine cabinet. 115/230Volt/1f/50-60Hz

Core Features:

- Adjustable delivery chute with V-block centering guide and pneumatic cylinder

- Wrap module with synchronized stepper motor drive and tool-less adjustment

- adjustable twin bar guide rails and emergency stop controls

- Variable speed control box mounted on machine cabinet

- Heavy-duty 304 stainless steel frame

- Automatic drip tray protects bottles from potential drips

- Photo sensor/counter system to ensure containers are in place prior to filling

- User-friendly Allen Bradley / Micrologix 1200 controls

Highlights

- Tool-less Change Over

- Variable Speed Control

- 24-7 Support

- Stainless Steel Construction

- User-Friendly Controls

- Deep-vented overflow nozzles

CUSTOM WINE & SPIRITS BOTTLING LINE REQUEST

Do you have a Distilled Spirits & Wine Bottling Line or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from complete lines like this Distilled Spirits & Wine Bottling Line to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)