Used Bevcorp 40 Valve Can Filler with Angelus 61h Seamer

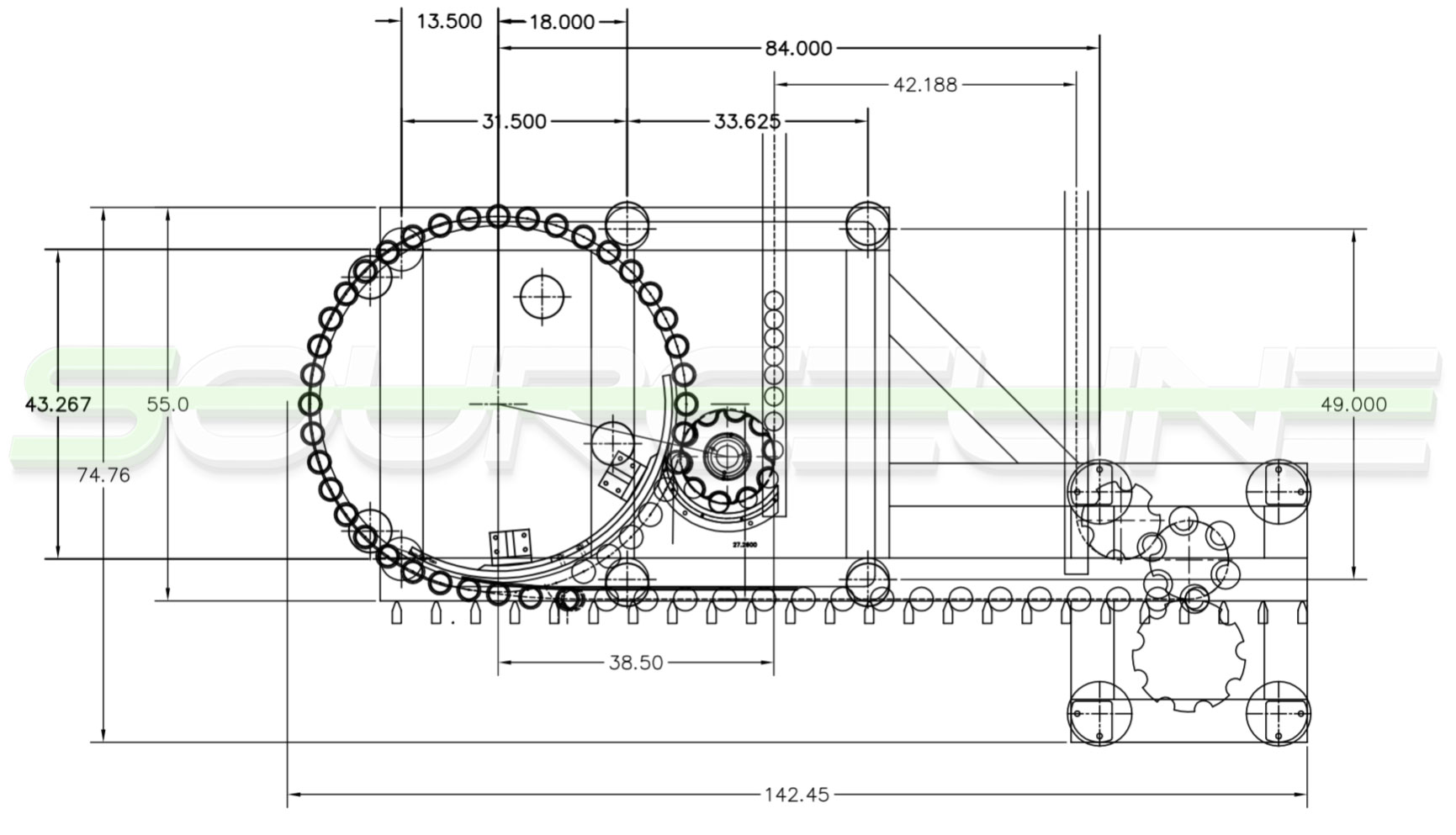

The Used Bevcorp 40 Valve Can Filler with Angelus 61H Seamer has a versatile operational capacity, previously running 12oz sleek cans with 202 ends at a speed range of up to 575 cans per minute. The unit is currently set up for 12oz sleek cans with 202 lids, featuring well-maintained chucks and rolls to ensure efficient canning operations. The equipment is equipped with an advanced Allen Bradley MicroLogix PLC control panel, providing precise control and monitoring capabilities. Additionally, there is a dedicated lubrication panel to maintain continuous performance. The seamer also includes an operator control station for user-friendly operation.

Previously running alcoholic seltzer on 12oz sleek cans up to 575 cpm. Available Now

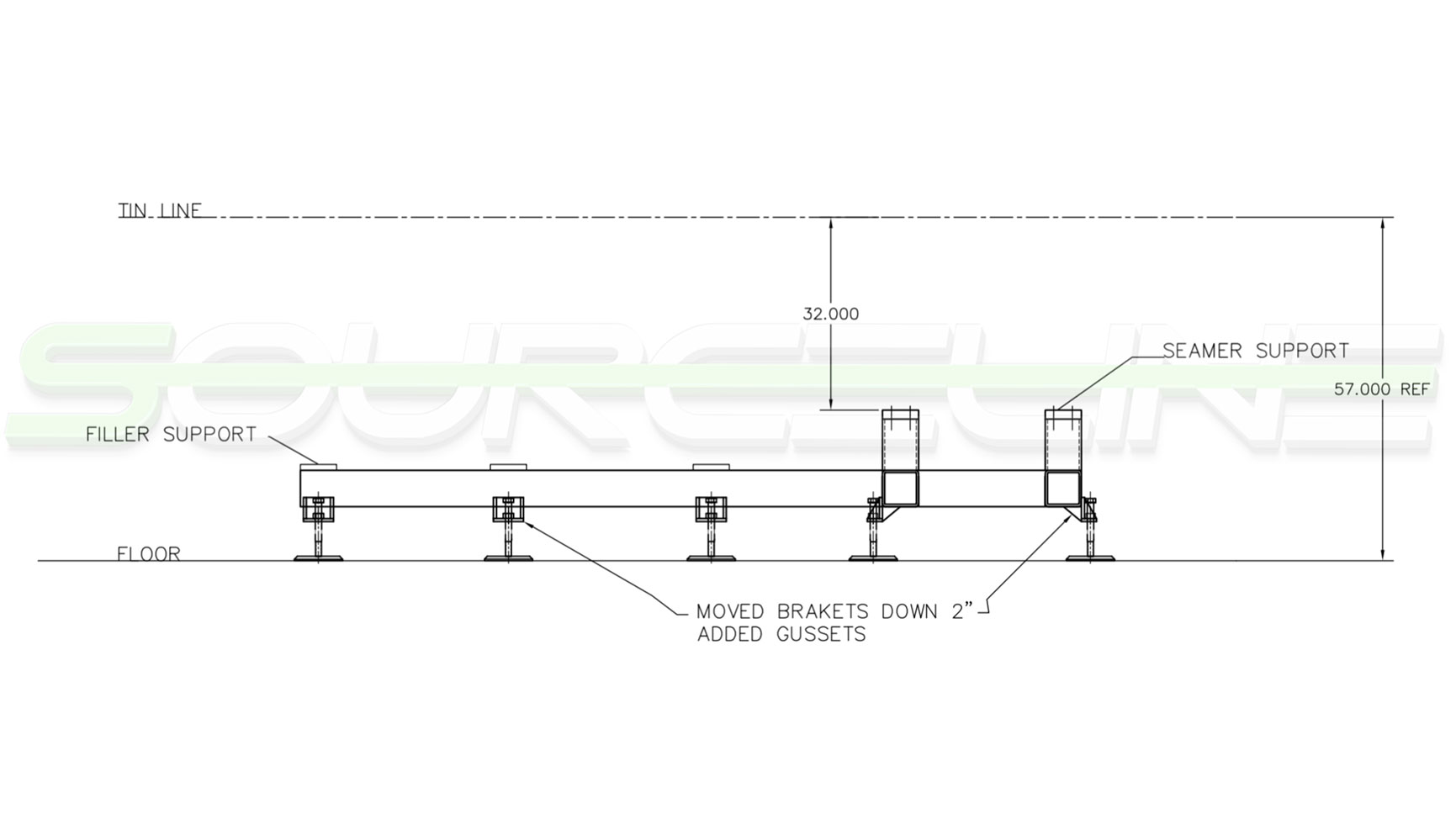

In addition to its core features, the Used Bevcorp 40 Valve Can Filler with Angelus 61H Seamer is supplemented with valuable additions, including a Chart liquid nitrogen dosing system, CO2/Nitrogen bubble breaker, mechanical guarding, operator platform, and extra handling parts. The structural integrity of the equipment is further reinforced by a common base frame, enhancing both durability and stability. This system was last used for packaging various beverages, including beer, seltzer, and CSD products, with a strong track record of reliable and top-quality production. Moreover, it has been subjected to regularly scheduled maintenance, ensuring its continued dependability. Bevcorp can fillers for soft drinks are recognized world-wide for their durability, reliability and consistently high output at low operating cost. Bevcorp can fillers are designed and built to be rugged and cost effective.

- Ten Port Orsco Lubrication System

- Chart liquid Nitrogen Dosing System

- Bev-Guard Category 2 Saftey Guarding

- Electronic Bowl Level with AutoCIP

- Operator Platform Included

- Allen-Bradley MicroLogix 1500 Processor

| Manufacturer | Crown |

| 40-F.T.69 | Over 575 cpm (12oz U.S.) |

| Filling Valves | 40 |

| Manufacturer | Angelus |

| 61h | 600 cpm (dia 50.8 - 108mm) (ht 41.3 - 203.2mm) |

| Seaming Stations | 6 |

Filler/Seamer/Lubrication Electrical Control Package

Distributed control over Ethernet to junction boxes mounted on machine and separate LAN network specifically dedicated to plant Ethernet network. Main control cabinet (installed by others) is Type 4X rated with air conditioning, lighting, Arc Flash protection of fused disconnect, and door interlock for operation of machine. Programming is in Logix5000 which all resides in the main control panel. Lube panel is a remote I/O location and all lube panel controls come from the PLC in the main control panel. Seamer Co2 gas panel is controlled through HMI. Upholding mechanism, valve opener and can stop control included. Allen-Bradley panel view will be pedestal mounted and contain Bevcorp’s custom screens for operation maintenance, and setup designed with maximum production time as the primary goal.

Ten Port Orsco and Single Pump Grease Lubrication System

SS enclosure (enclosure installed by others) with alarm indicator light assembly. Maximum distance for location is no more than 20 lineal feet from the filler. Automated oil and grease lubrication via: Orsco oil injection metered oiling system for continuous guide rail and lift cylinder end lubrication. High pressure greasing system for flexible time interval greasing of bearings and bushings. High flow air distribution system for precision air regulation to filler controls air supply.

Do you have a Used Bevcorp 40 Valve Can Filler with Angelus 61h Seamer or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Used Bevcorp Crown 40 Valve Can Filler with Angelus 61H Seamer to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086MAILING ADDRESS

6081 Hamilton Blvd, Suite 600

Allentown, PA 18106, US

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

6081 Hamilton Blvd, Suite 600

Allentown, PA 18106, USOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)