Rebuilt KHS Can Filler with Angelus 121L Seamer

| Condition | Rebuilt |

| Category | Can Fillers, Can Seamers - Closers, Fillers - Filling Equipment, Rotary Fillers |

| Manufacturer | Angelus, KHS |

| Model | 121L, 94 Valve |

| Year | 2019 |

| Industry | Beverage, Brewery |

| Speed | 1200 CPM |

| Location | North America |

| Stock Number | 1912-200623 |

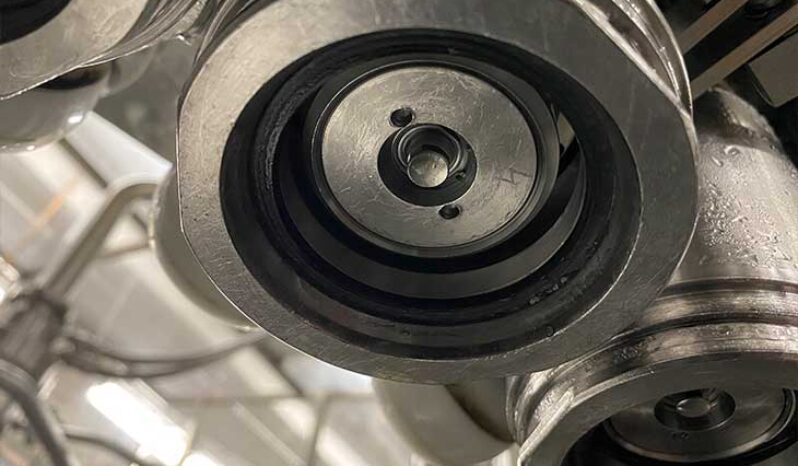

This Rebuilt KHS Can Filler with Angelus 121L Seamer was rebuilt in 2019 and has been well maintained. The system was previously running cold fill CSD beverages on 202/204 x 602 12oz sleek cans. The KHS 94 valve can filler and Angelus 12 Spindle Seamer are both set for 202 ends and are mounted on a common base. Capable of speeds up to 1200 cans per minute.

previously running cold fill CSD beverages on 202/204 x 602 12oz sleek cans. Available Now!

- Rebuilt in 2019

- Running Sleek Cans

- Well Maintained

- Available Now

| Filling Valves | 94 |

| Seaming Heads | 12 |

| Current Settings | 202/204 x 602 (12oz) |

| Filler Dimensions | 139"L x 133"W x 111"H |

| Filler Dimensions (with Frame) | 146"L x 145"W x 125"H |

| Machine Weight (with Frame) | 21,400lbs (9727kg) |

| Filler Shipping Weight (with Frame) | 23,650lbs (10750kg) |

| Load Per Leg On Floor (Filler with Frame) | 2,675lbs (1216kg) |

| Load Per Leg On Floor (Filler Only) | 2,189lbs (995kg) |

Rebuilt H&K Sigma 92V Filler

Includes quick change parts for 202/204 x 602 sleek Cans, a stainless-steel painted cast iron frame, new slew ring, complete can handling parts replacement, height adjustment system with drive, new fill tubes, trip levers, tulip actuators, closing cam and wear strip package, new infeed belt drive and worm drive gearboxes, CIP cup assemblies, new center column, new Filler control panel w/Allen Bradley controls, set-up for air-veyor infeed. Electrics 480V-3Ph-60Hz.

Rebuilt Angelus 121L Seamer

Includes 12-seaming heads, electronic clutch on seamer, new seamer wiring package, feed chain plate and assembly, paraflex coupling, double bubble breaker assembly, rebuilt filler gear drive, ultra-high efficiency 40hp motor, rebuilt CIP system, new gasser panel, and standalone grease pump.

Do you have a Rebuilt KHS Can Filler with Angelus 121L Seamer or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Rebuilt KHS Can Filler with with Angelus 121L Seamer to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

Main: (484) 553 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

Main: (484) 553 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)