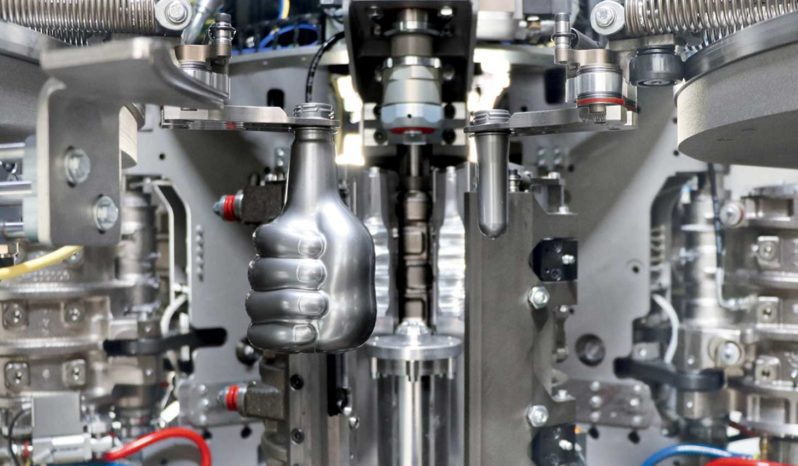

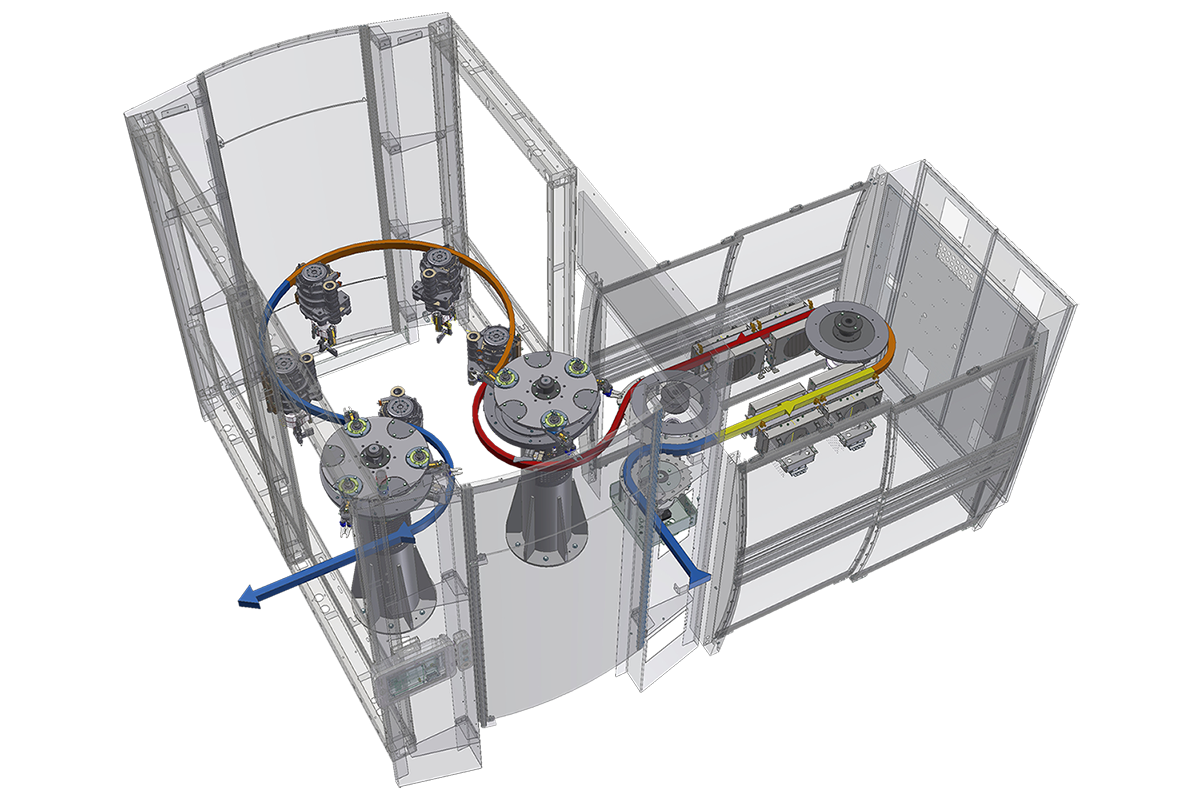

The Rotary Stretch Blow Moulder (EBS ERGON Series) ensures high performances in the stretch blow-moulding of PET, PEN and PP bottles, mainly used in the “food & beverage” sector. Thanks to high-tech components, minimized maintenance and operational costs and excellent quality/price ratio, this unit is the ideal solution for the production of plastic containers of different capacities, featuring various shapes, from the most simple to the most sophisticated ones.

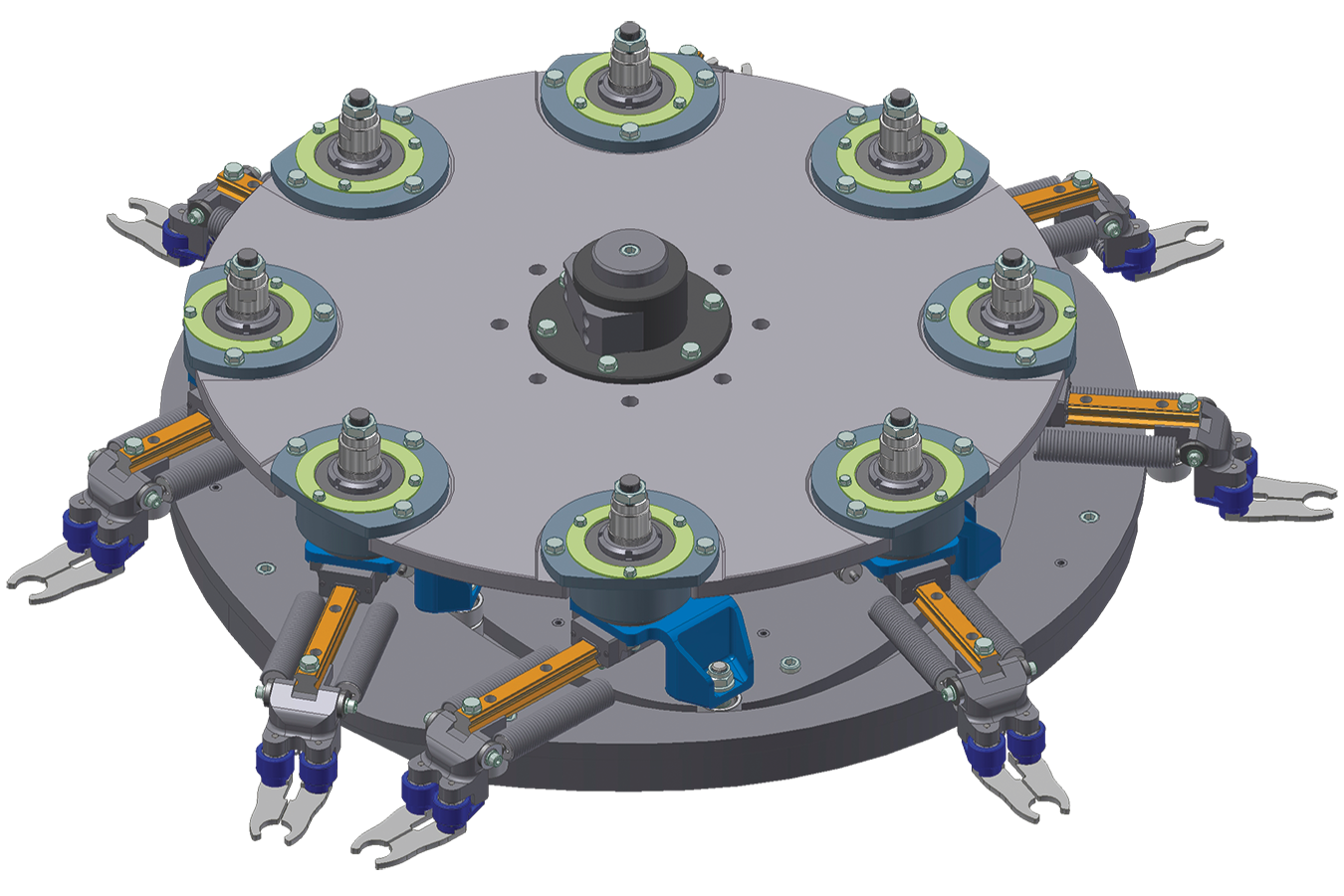

This Blow Molder is composed of 7 models, from 4 to 16 cavities, suitable for the production of bottles up to 3 litres, with a maximum output of 8,800 bph (1 L) to a 33,600 bph (1 L)

The Rotary Stretch Blow Moulder of the EBS ERGON series stands out for their compact, ergonomic and functional configuration, capable of considerably simplifying the operations of machine management, cleaning and maintenance and of assuring significant space savings within the bottling facility.