Used 20 HL IDD HEBS Brewery System

| Condition | |

| Category | Brew Houses |

| Manufacturer | IDD |

| Model | HEBS |

| Year | 2012 |

| Industry | Brewery |

| Capacity | 20HL |

| Location | North America |

| Stock Number | 1912-181007-09 |

The Used 20 HL IDD HEBS Brewery System is able to provide maximum efficiency and low environmental impact with an output of up to 60,000 Hl (50,000 bbl) per year. The use of any fermentable grain or cereal is possible (malted and non malted). A brew every two hours is possible (instead of a brew every five to seven hours). 20 to 35 percent less water usage (no weak wort). 10 to 15 percent less grain used. Up to 98 percent extract. Rapid starch conversion (less than 40 minutes). 65 percent spent grains solids (no wort wasted). Less energy due to less water pumped and fast turnaround per brew (you can turn the lights off earlier).

This 20HL High Efficiency Brew System has an output of 60,000 HL (50,000 BBL) per year. Available Now

The Used 20 HL IDD HEBS Brewery System is completely skid mounted, pre-piped and wired for fast installation. High degree of automation and control via Allen Bradley PLC & HMI. Brew style flexibility and innovation not possible on a Standard System. Up to 10 percent better hop utilization.Double the output by adding another set of brewhouse tanks and work platform to the mash filter.

- Good Condition

- 20% to 35% less water usage

- 10 to 15 % less grain used

- 60,000 HL output per year

- Allen Bradley PLC & HMI

- Available Immediately

2+2 AquaFew System

Footprint 12’L x 8’W x 8’H

Fine Grinding Mill, Grist Hopper & Augers

1,500 lb. 304 stainless steel grist hopper with hinged access lid. 5 HP explosion proof motor and controls. Access platform and stairway in 304 stainless steel. Screw Auger. 150 lb. grain dump bin, bag slitter in 304 stainless steel with auger.

Footprint 6′ x 6′ 10′ overall height (excludes access steps)

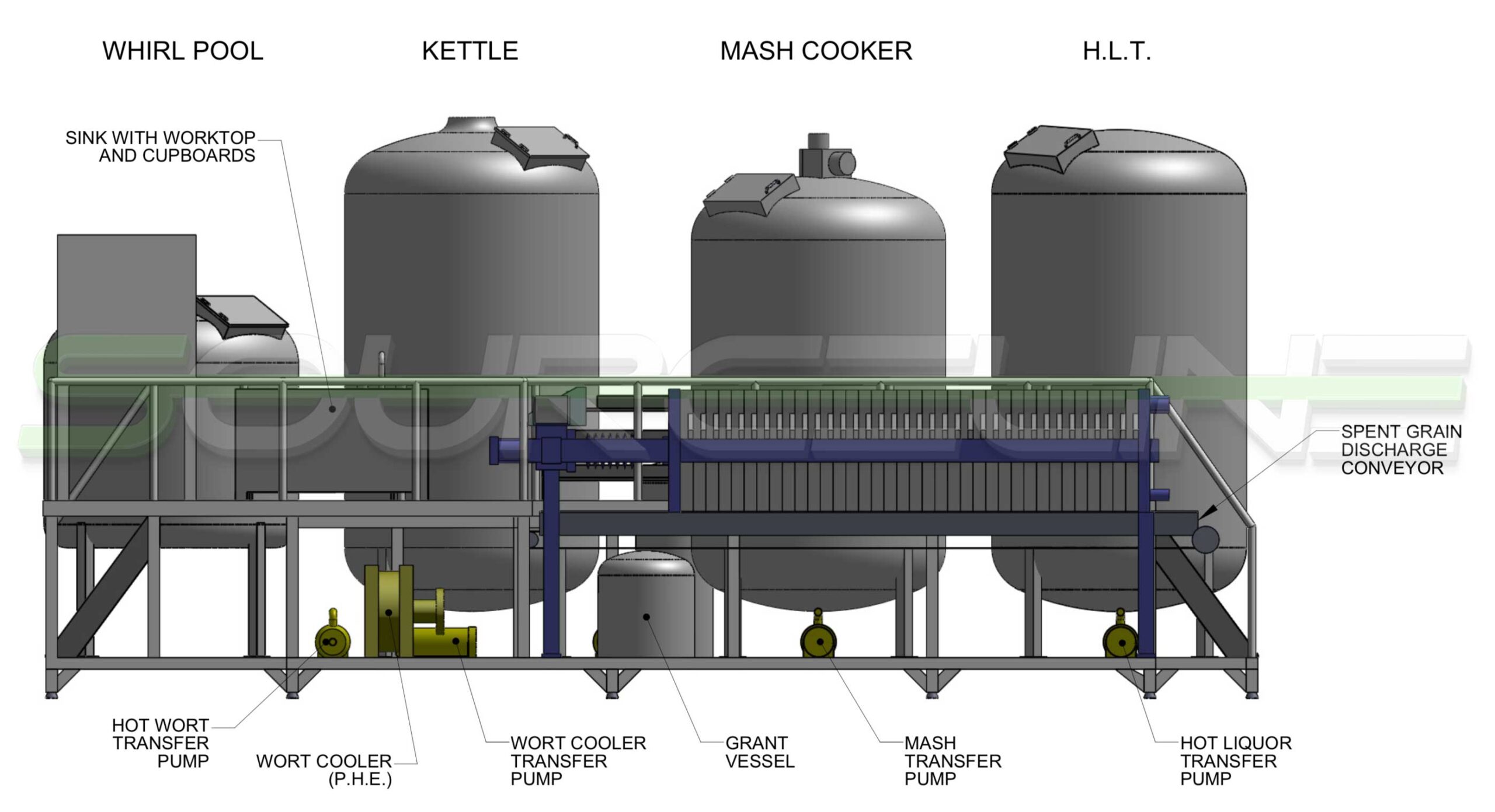

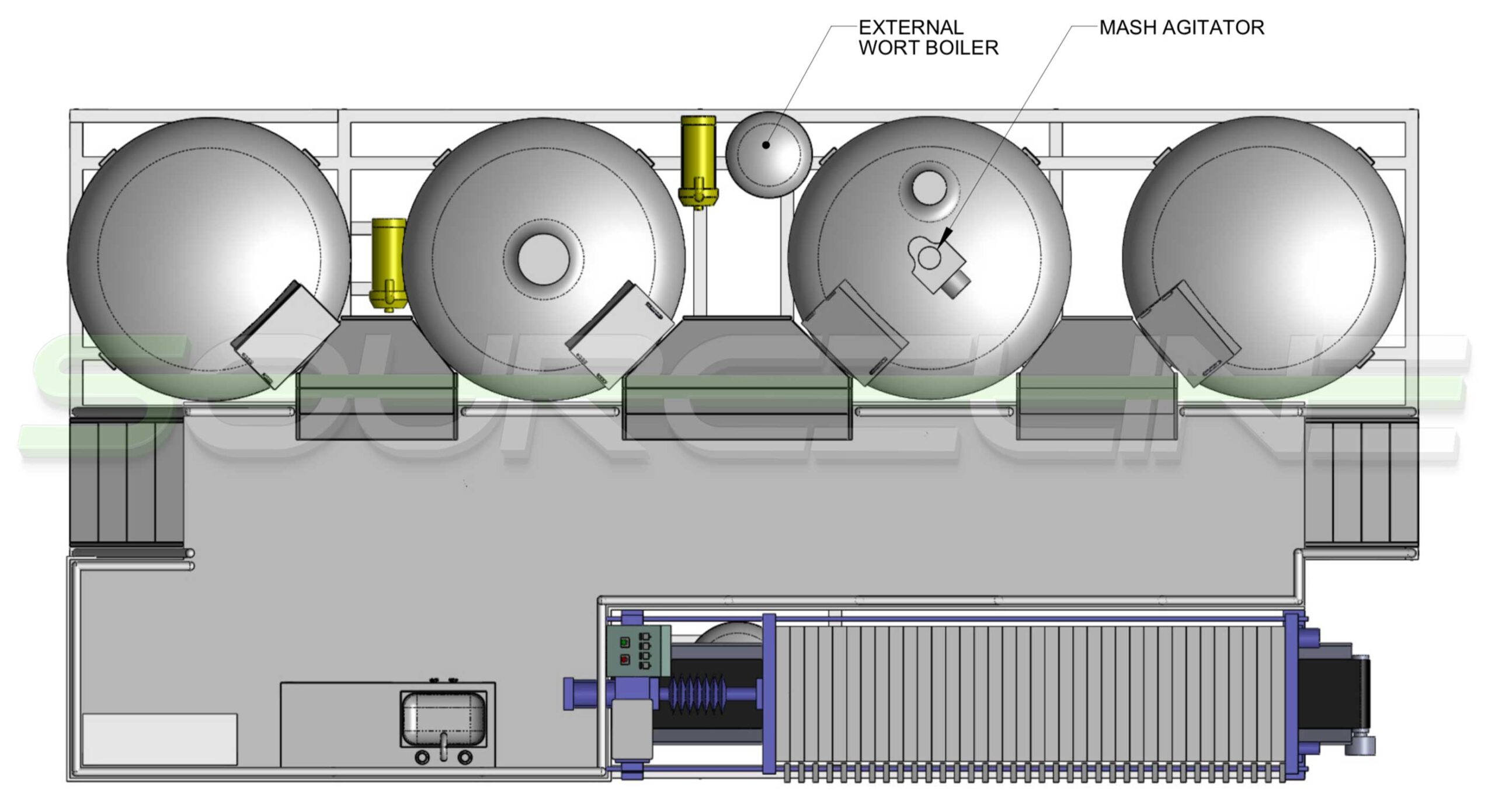

40 HL Hot Liquor Tank w/ 30% Headspace

304 stainless steel. 60″ ID x 72″ side wall. 10 gauge domed top and bottom heads. 10 gauge side walls. 2″ thick insulation. 12 gauge cladding # 2 finish. 1″ sch. 40 stream coil, condensate return, with temperature control via HMI. Dial thermometer and pocket. 1.5″ inlet and outlet and drain valves. 1.5″ vent tube.

Footprint 5.5′ dia. x 11′ overall height – Mounts on Brewhouse skid

20 HL Mash Vessel w/ 35% Headspace

304 stainless steel. 60″ ID x 48″ side wall. 10 gauge domed top and shallow bottom heads. 10 gauge side wall with 30″ deep steam jacket. Steam jacket with temperature control via HMI. 1.0″ steam jacket supply and 1.0″ condensate trap and return. 2.0″ insulation on sides. Grist hydrator. 8.0″ stainless steel vent collar with condensate lip and drain. CIP 360 degree spray spinner with down tube. 16.0″ x 20.0″ manway. 2 HP top mount VFD gear drive, with agitator assembly. 3″ outlet and drain valve. Dial thermometer and pocket. RTD and pocket for remote temperature control. 12 gauge cladding # 2 finish. 3″ TC sight glass. Fow- (4) SS legs.

Footprint 5.5′ dia. x 11.5′ overall height – Mounts on Brewhouse skid

20 HL Internal Calandria Brew Kettle (35% Headspace)

304 stainless steel. 60″ ID x 54″ side wall. 10 gauge deep domed top and shallow bottom heads. 1.0” sch. 40 supply to kettle bottom and calandria steam inlet and condensate outlet. 2.0” insulation on sides and bottom. 12.0″ stainless steel vent collar with condensate drain. 16 gauge sectional vent with china hat on top. CIP 360 degree spray spinners with down tubes. 16.0″ x 20.0″ manway. 1.5” inlet, outlet and drain valves. Internal calandria cylinder 24″ diameter x 30″ high 10 gauge, l” OD tubes, inverted china bat deflector 30″ diameter, 12 gauge. Steam jacket on kettle bottom, 10 gauge. One dial thermometer and pocket. RTD and pocket for HMI remote temperature control. 1” Dewer proportional steam control valve. 12 gauge cladding# 2 finish. 12 gauge bottom cladding. 3” TC tank light. Fom (4) SS legs.

Footprint 5.5′ dia. x 11′ overall height – Mounts on Brewhouse skid

Mash Filter for 20 HL Brew Length

30 cu. ft. capacity. 3 9 x 800 x 800 mm chambers. 98% plus extract – up by 10% or more compared to a Lauter Tun. 20% less water usage than a Lauter Tun. 65% spent grain solids – up by 25% or more compared to a Lauter Tru1. 2 hour tmnarormd tinle between brews. All contact components are FDA-GRAS. The steel frame is 2 part epoxy coated with optional galvanized spray prior to paint. Filter plates are polypropy Jene in a mixed pack format. ( one solid plated and one membrane squeeze plate per chamber- 2″/50 mm). Media cloths are made with FDAGRAS polypropylene material. Hydraulic cylinder is steel with chrome plated piston covered by a boot with same exterior coating and options as the steel frame; to run at 4000 PSI. Hydraulic pump system uses vegetable oil and is pneumatically operated. Membrane Squeeze system supply constructed from 304 stainless steel pipe with polyethylene tube connected to each membrane plate. Filter press side bars will have 304 stainless steel caps.

Footprint 4’W x 13’L x 6’H – Mounts on Brewhouse Skid

Wort Transfer Pump & Spiral Hopback

304 stainless steel. 2 HP progressive pump. 100 liter (26.5 gallon) conical hopsack with conical screen. CIP/SIP Spray ball. Dual “sock” trap. Valves, fittings to swing links.

Wort Cooler Plate Heat Exchanger & Wort Aeration System

Brewhouse Piping, Valves, Transfer Panel & Pump

- 304 stainless steel

- 1.5″ OD wort piping for transfer

- 1.5″ OD water piping

- 2 HP centrifugal pump

- Valves, fittings and swing links

Brew house, FV & BBT Central Control Panel

NEMA 4 (IP65) enclosure. Allen Bradley compact Logix PLC. Allan Bradley PanelView Plus Color HMI. Steam kettle control. Mash vessel temperature control. Lauter temperature control. Wort cooler control. All motor controls. Vessel light controls. UL/CUL certified.

All the above equipment mounts on the brew house skid

Brewhouse Skid

Footprint 21’L x 13’W x 1’H built in sections for shipping

Tank Farm (FV & BBT) Remote Controls (5 each)

Mounted on each individual tank

Hose Bath & Cellar Equipment

Mobile 3’W x 20’L x 4’H

Yeast Kegs - Propagator / Storage

Hot Liquor Pump

- 304 stainless steel

- Valves and hard piping

- 1.5 HP 220/440-3-50/60Hz

Work Platform

- 304 stainless steel

- OSHA approved steps, kick and handrails

- Mounting brackets for control panel

| 20 HL Mash Vessel Heating Jacket | 48 sq. ft. at 0.134 gal. per ft(sq) = 6.43 gallon |

| 20 HL Kettle Bottom Heating Jacket | 13.97 sq. ft. at 0.134 gal. per ft(sq) = 1.87 gallon |

| 20 HL Kettle Internal Heater | 67.81 sq. ft. at 44.98 gallon |

| 40 HL Hot Liquor Vessel Heating Coil | 37 sq. ft. at 6.01 gallon |

Do you have a Used 20 HL IDD HEBS Brewery System or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Used 20 HL IDD HEBS Brewery System to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)