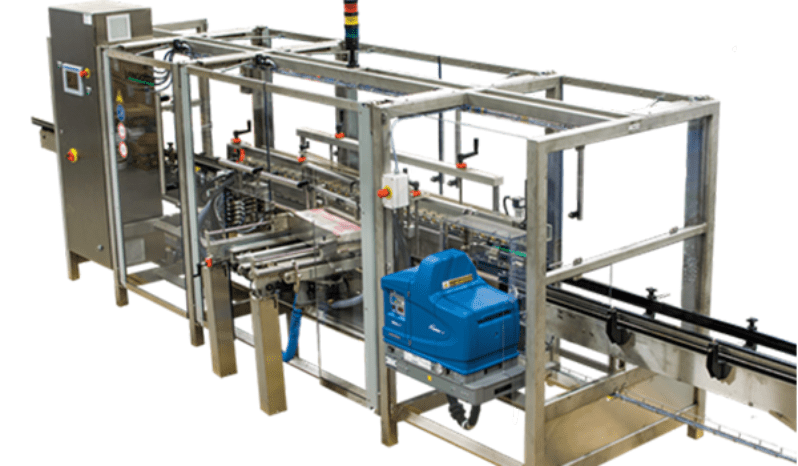

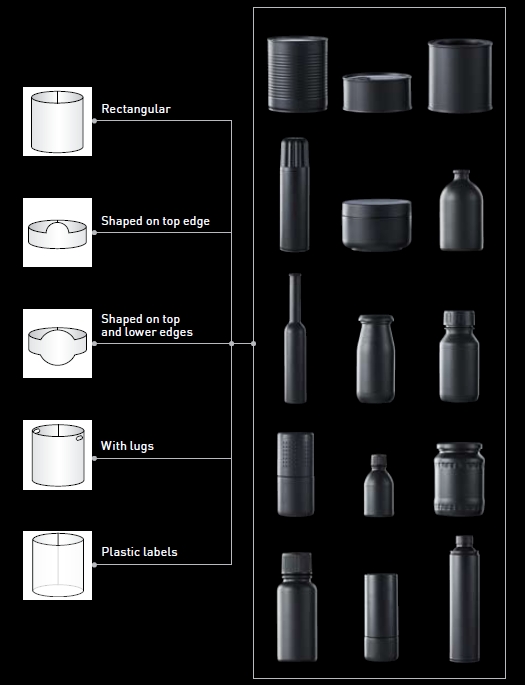

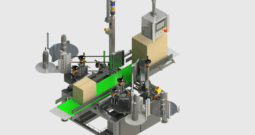

The Langguth Hot Melt Inline Labeler represents the best value point of any changeover labeler. Combining high output, mechanical simplicity, very easy changeover with minimal investment in change parts, this labeler obviates rotary bases in most hot melt applications with cylindrical containers. Uniquely versatile the Hot Melt Inline Labeler provides an adjustment range including steel cans, glass jars, plastic bottles including gallons and paint cans with handle ears. Moreover the unique hot melt spray glue system reduces glue consumption to bare minimum. This unit has the lowest cost of ownership, while increasing overall operational up-time.

Delivers speeds up to 60.000 labellings containers per hour

The machine model hotLAN® 310 is the inline high-speed hot melt cut and stack labeller from LANGGUTH. The labeler‘s glue-saving hotmelt Technology delivers speeds up to 60.000 labellings containers per hour; for virtually all round containers receiving wraparound labels. Set-up times of 5–10 minutes as well as nonstop operation contribute to high uptime and Efficiency for your production line – important economic considerations for companies working continuous multi shift operations at peak performance throughout the year. The integration of coding or other control devices and reject functions provide a high-quality labelling solution and an immediate checkpoint for quality control within the line.