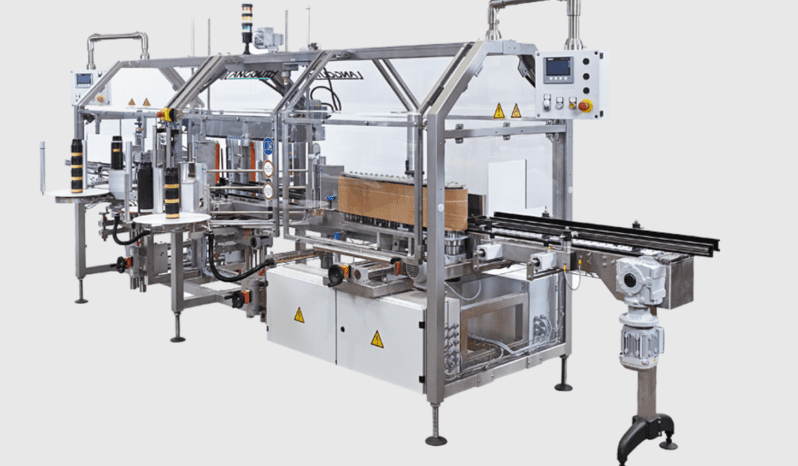

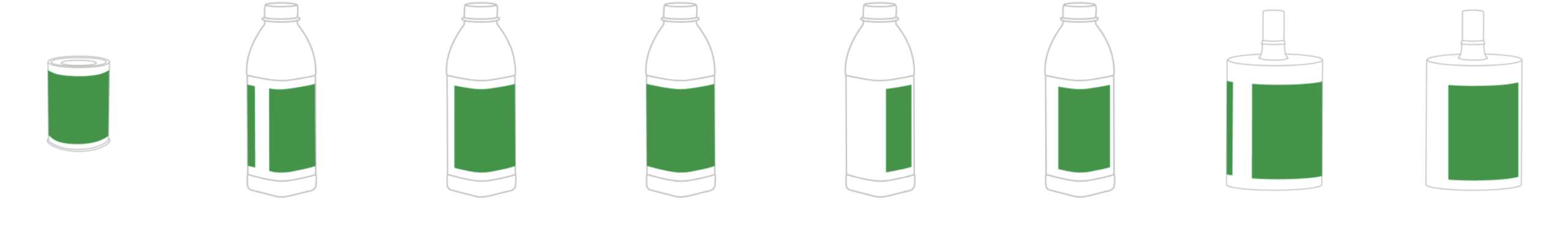

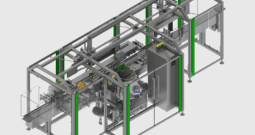

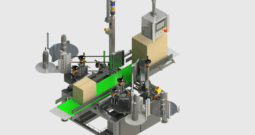

The Langguth Pressure Sensitive Inline Labeler provides unmatched flexibility in running pressure sensitive labels with multiple container shapes. This unit uses robust inline frame with state-of-the-art pressure sensitive heads. Additionally for large pressure sensitive labels the unit is able to apply wrinkle free material even to tapered containers.

Dispenser speed of 200 m/min possible

This unit meets the labeller demand for nearly all round containers and many non-round shapes receiving a single or multiple labels. Automatic adjustments, nonstop operation, various marking technologies or code readers can be incorporated. The labeller contributes therefore to high uptime and efficiency of your production line. High-quality engineering, robustness as well as fast, repeatable changeovers highlight just some of the longterm benefits of this labeller.