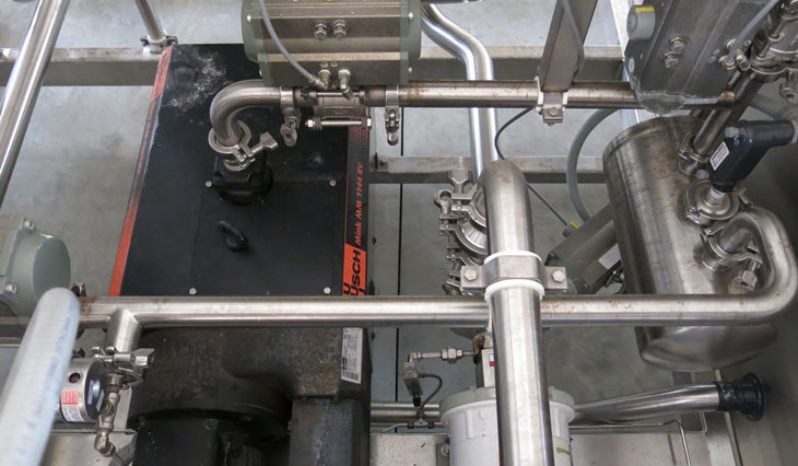

This Used MicroBlend Beverage Processing System reduces oxygen and nitrogen levels in the blended product and has a capacity up to 10,000 Gallons/Hour. This stainless steel constructed bling system allows product to achieve low parts-per-billion levels of O2 and N2. Deaeration occurs without the use of water deaeration. The system uses Mass Flow Meters to measure the syrup, water and CO2 streams with blending ratios ranging from 2-to-1 to as high as 30-to-1. All quality, yield, efficiency and production records are displayed in real time as well as logged for review and can be ported to a supervisory computer.

MicroBlend blending system has less than a two (2) year payback. Upgrades and customizations available upon request.

This MicroBlend Beverage Processing System is the only patented mass-flow based multi-stream blending system that offers precision blending to an accuracy of ± .1% with a repeatability of ± .025%. The MicroBlend system has achieved its ability to measure, blend, carbonate and calculate product strength and yield information due to the capabilities of the Micro Motion Elite Mass Flow Meters and the specialized software developed for this process.