2007 Krones 66 Valve Volumetric Filler with 22 Head Alcoa Capper

| Condition | |

| Category | Beverage Fillers, Fillers - Filling Equipment, Rotary Fillers, Volumetric Fillers |

| Manufacturer | Alcoa, Krones |

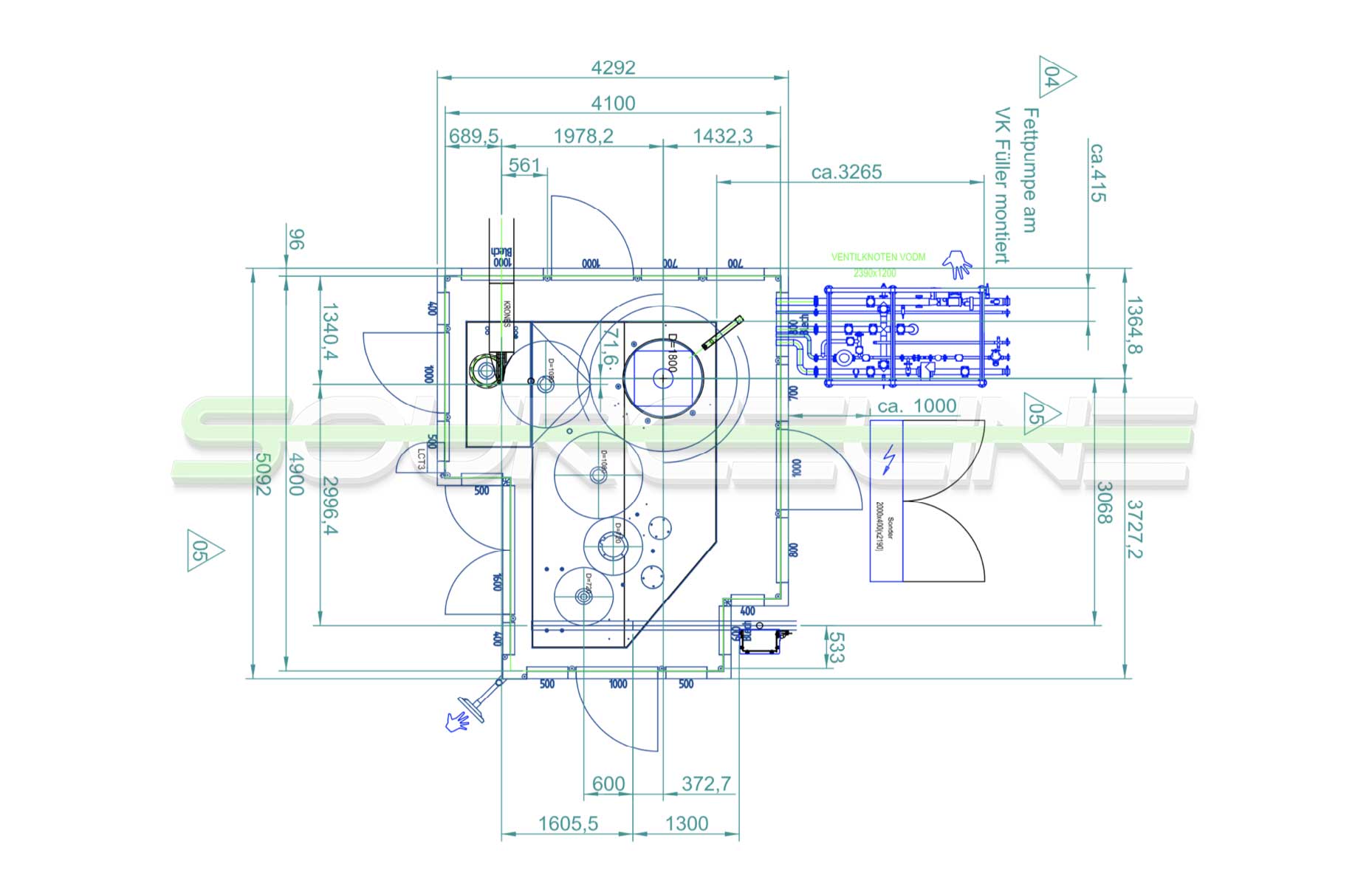

| Model | VODM-PET 2.160-66-103 |

| Year | 2007 |

| Industry | Beverage |

| Speed | 400 BPM |

| Location | North America |

| Stock Number | 0209-191107 |

This 2007 Krones 66 Valve Volumetric Filler with 22 Head Alcoa Capper was last running non-carbonated juice filling 710ml PET bottles at 310BPM. The Volumetric VODM series is the ideal solution for conductive products to be filled, because with this system the fill quantity is accurately measured via an inductive flow meter. All filling process steps can be programmed easily and individually and can be performed via the the electro pneumatic controller adjusted to the product to be filled and to the container. The well proven filler is distinguished by its high reliability during continuous operation.

Previously running at 310 bpm per minute. Currently set for 710ml PET bottles. Hot Fill Capable

| Filling Valves | 66 |

| Capping | 22 |

| Handling | Neck |

| Machine Pitch | 94 mm |

| Pitch Circle Diameter | 2,160 mm |

| Electrical | 230-460V-60Hz-3Ph |

| Applications | Non Carbonated - Water - Pulp/Fibres - Hotfill |

| Type Designation | Volume - Flow Metering - Polyethylene Terephthalate |

Method of Operation

Prior to filling, the product is guided to a product tank which is designed as a central or a tubular ring bowl depending on the pitch circle, and which is connected to the filling valves via the product feed pipes. In each connecting pipe, there is an inductive flow meter which measures the quantity of the product flowing through the pipes via the product’s conductivity. Filling begins after centering or after the container being pressed-on and it is performed via the free jet method or for hot filling with pulp and fibres via swirling. In order to be able to cope with the different bottles and products to be filled, one or two filling speeds are available. Non- carbonated beverages are filled pressure-less in multi-chamber operation. Once the preprogrammed amount of liquid has flown into the container, a flow meter signal will trigger closing of the valve. The fill parameters and programs are stored in the controller making quick change-overs via touch-screen selection possible.In addition to the neck handling version, fillers with base handling feature are also available for filling containers without neck ring or HDPE bottles.

Do you have a Used Krones VODM Volumetric Filler or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from single units like this Used 2007 Krones 66 Valve VODM Volumetric Filler to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

Main: (484) 553 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

Main: (484) 553 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)