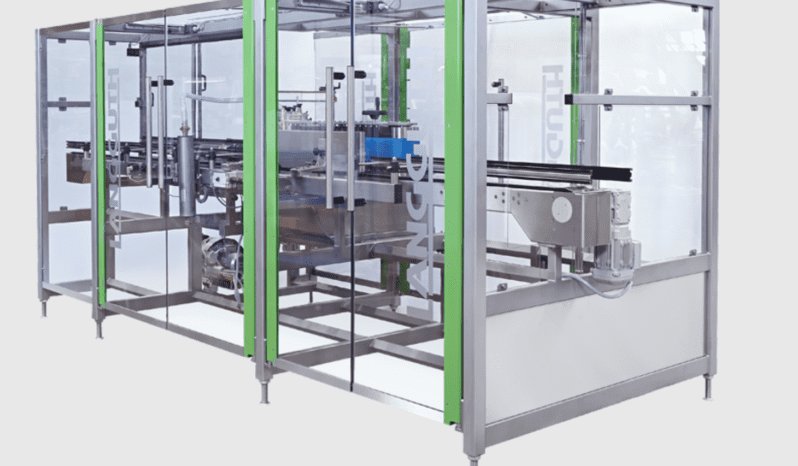

Langguth Wet Glue Inline Labeler

| Condition | New |

| Category | Inline Labelers, Labelers - Labeling Equipment, Wet Glue Labelers |

| Manufacturer | Langguth |

| Model | wetLAN 110 |

| Industry | Beverage, Brewery, Distillery, Food, Nutraceutical, Winery |

| Speed | 400 CPM |

| Location | Europe |

The Langguth Wet Glue Inline Labeler achieves steady state speeds to 400 bpm – without bottle plates or glue pallets. Commonly used with spreads, sauces, dressings, and condiments the wetLAN 110 of inline wet glue labelers are optionally equipped in full stainless for brine environments. Also found in paint and chemical environments, variants of the wetLAN 110 series of inline wet glue labelers offer full ATEX and Class 1, Division 1 construction for hazard EX-Proof environments.

Inline models provide lowest cost of ownership

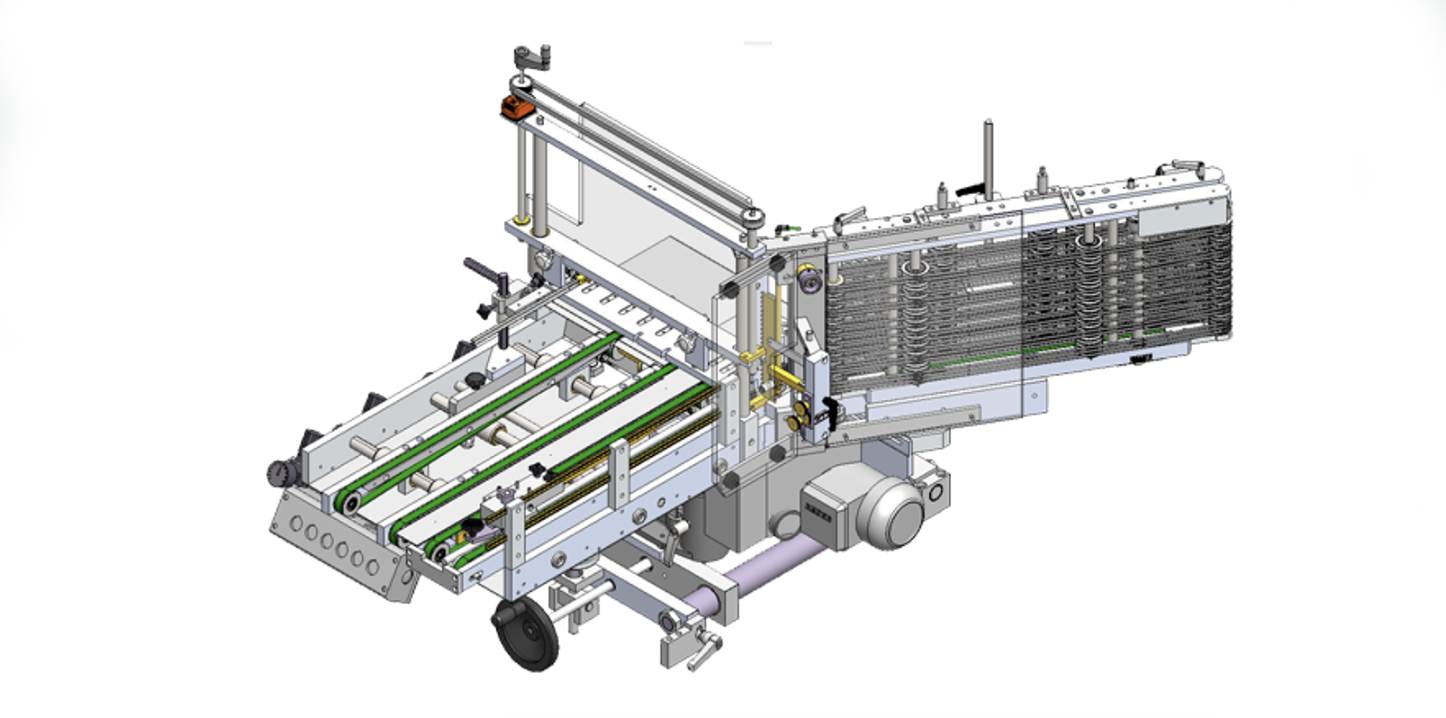

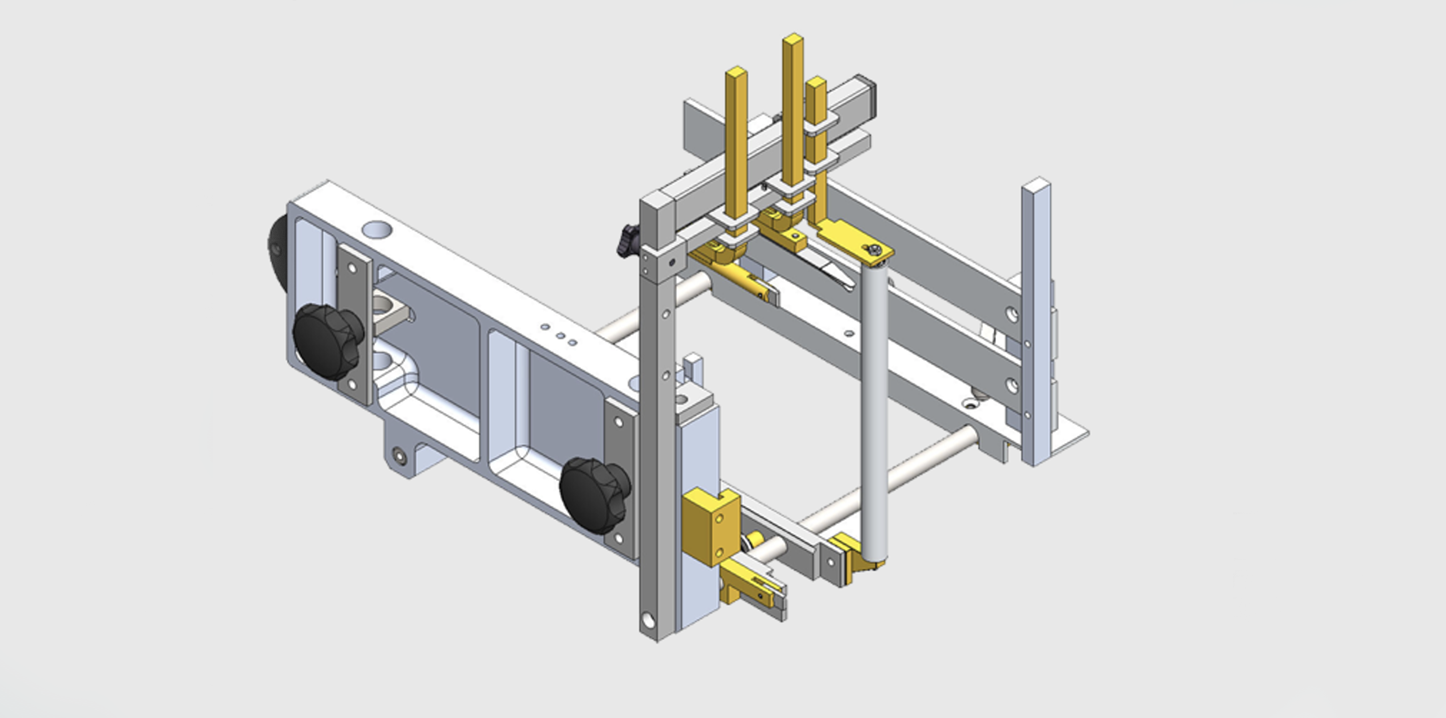

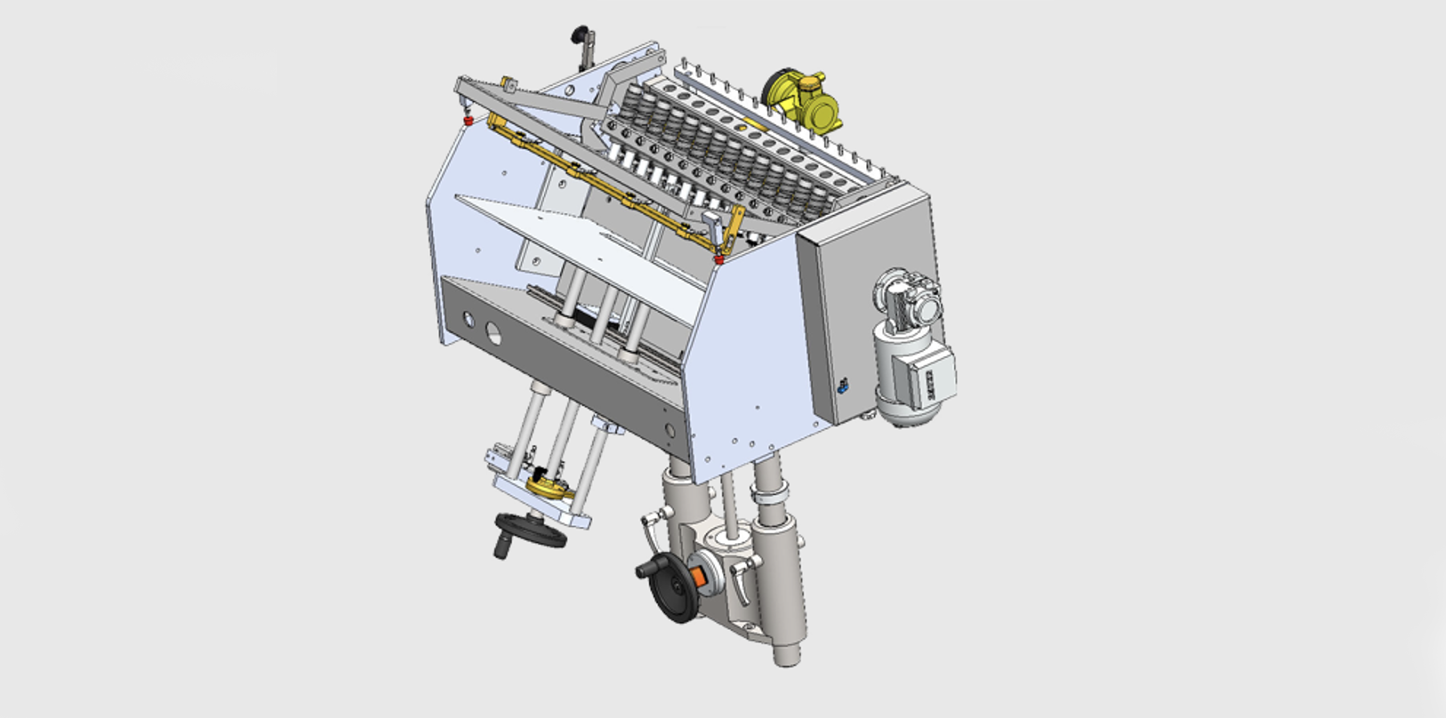

The flexible wetLAN 110 inline labeler specializes in labelling multi-size round containers receiving a single label – patch or wraparound. To optimize performance the wetLAN 110 includes three unique, easy changeover label magazine options. The wetLAN 110 is unmatched in the industry for its adjustment range – handling small and large label and container combinations, plus its ability to be sized for slow and high speed operation. Available options include bar code scanning, reject, orientation, label/container marking, tamper evident, and lid labelling.

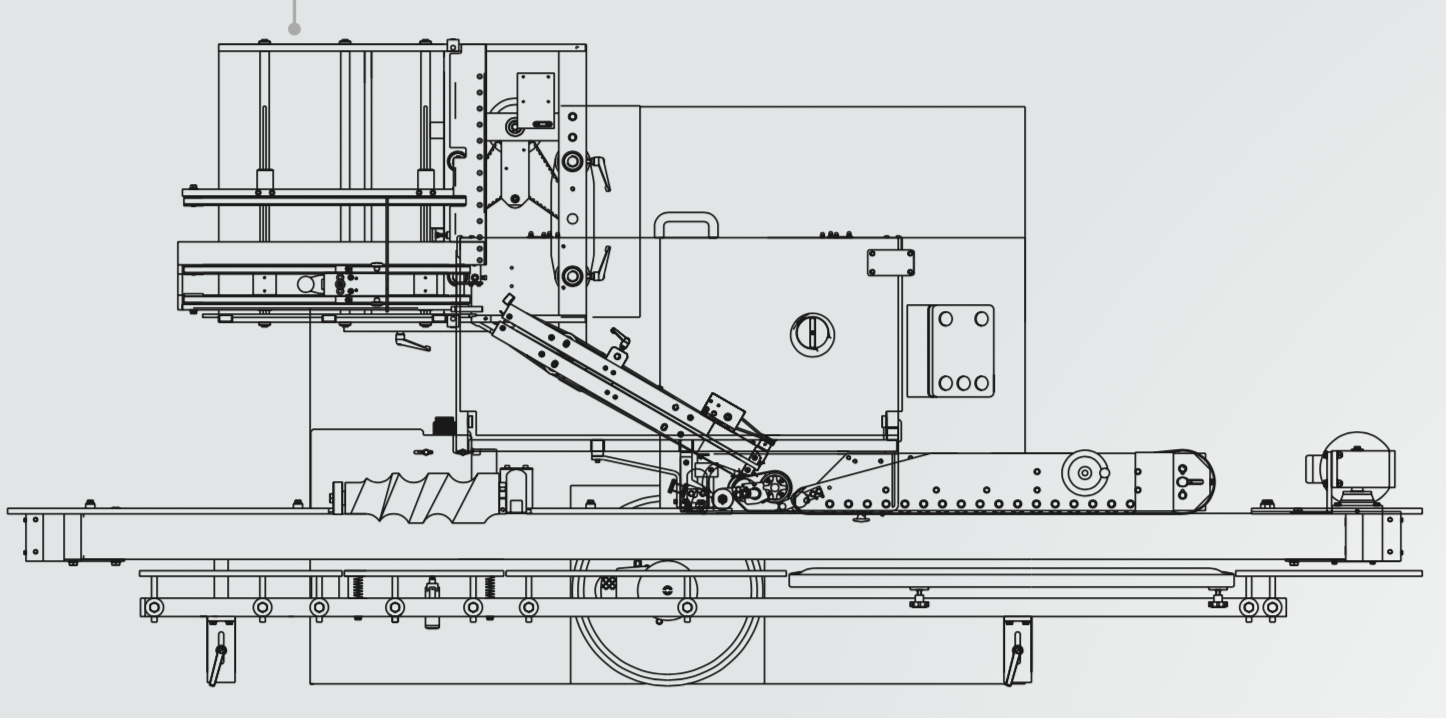

Equipment Operation

The labeler’s conveyor chain carries containers through the inline labeller. At the infeed a metering device creates a repeatable gap between containers, initiating progressive labelling processes. As a metered container is released a photo eye activates the label magazine. A label is separated from the stack in the magazine and guided past the glue roller. The glue roller applies a very thin and uniform glue layer onto the backside of the label. The conveyor chain speed and magazine label release are timed to achieve accurate label pick up by the container. Subsequent to label pick up, the container moves into the roll-on station where the label is securely affixed to the container.

Equipment Highlights

- Wraparound Label

- Front Label

- Front & Back Label

- Guarantee Label

- Multi-ply Label

| Basic frame: | Welded stainless steel square tube |

| Machine dimensions: | Depending on machine design, L 2.300 x W 1.700 x H 1.730 mm |

| Label magazine: | Oscillating magazine with Labels loaded in vertical position |

| Container: | Round containers |

| Container Ø: | Min. 40 mm |

| Label length: | Min. 80 mm, max. 395 mm (optional max. 570 mm) |

| Label height: | Min. 40 mm; max. 315 mm |

| Speed: | 4.000-7.000 containers / h max (depending on machine configuration as well as container and label sizes) |

| Conveyor belt height: | 820-920 mm |

| Basic frame: | Welded stainless steel square tube |

| Machine dimensions: | Depending on machine design, L 4.500 x W 1.600 x H 1.750 mm |

| Label magazine: | Stationary magazine with Label loaded in vertical Position, labels added with labeler at full speed, without interruption |

| Container: | Round containers |

| Container Ø: | Min. 40 mm |

| Label length: | Min. 80 mm, max. 400 mm |

| Label height: | Min. 40 mm; max. 315 mm |

| Speed: | 24.000 labels / h |

| Conveyor belt height: | 820-940 mm |

| Basic frame: | Welded stainless steel square tube |

| Machine dimensions: | Depending on machine design |

| Label magazine: | Stationary magazine with label storage in horizontal position for large labels |

| Container: | For large cylindrical containers up to 5 kgs + cans with handle (eyelets) |

| Container Ø: | Up to max. 200 mm |

| Label length: | 130-650 mm |

| Label height: | 50-315 mm |

| Speed: | 3600 containers / h (depending on label length) |

Key Features

- Contoured, square, oval, F-style, and cylindrical containers

- Up to 400 cpm

- Adjustable label magazine accepts spot, full wrap, shaped and rectangular labels

- Short linear footprint fits almost any line

- Simple 10-15 minute changevoer

- Highly flexible

Advantages

- Patch and wraparound labelling

- High efficiency due to fast conversion and easy operation

- Minimal investment in size parts

- Attractive Purchase price – economic operation

- Compact design

- Low unit costs

- Maximum uptime

CUSTOM LABELER REQUEST

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)