The Dual Lane Can Filling System is an American-made fully-automated can filling system that can be operated by 1 person to achieve 80 cans/minute throughput while in a highly compact footprint. This system features a Twin Monkeys Cimarron canner comprised of: (2) 5-head can CO2 pre-purge station, (2) 5-head can fill station that includes; Automated brite tank pressure controller to regulate the pressure of the beverage for repeatable timer-based filling on all fill heads, Balanced pre-fill manifold with no isolated high areas that can trap gasses, Automated lid dispenser, (2) lid sleeves (each capable of holding a sleeve of can ends), (2) generation 2 Patent-Pending industrial seamer station with one servo can loader. VFD-controlled washdown conveyor.

Currently set for 12oz sleek (204.5 dia / 202 LOE), capable of 80cpm. Never Used and ready for immediate delivery.

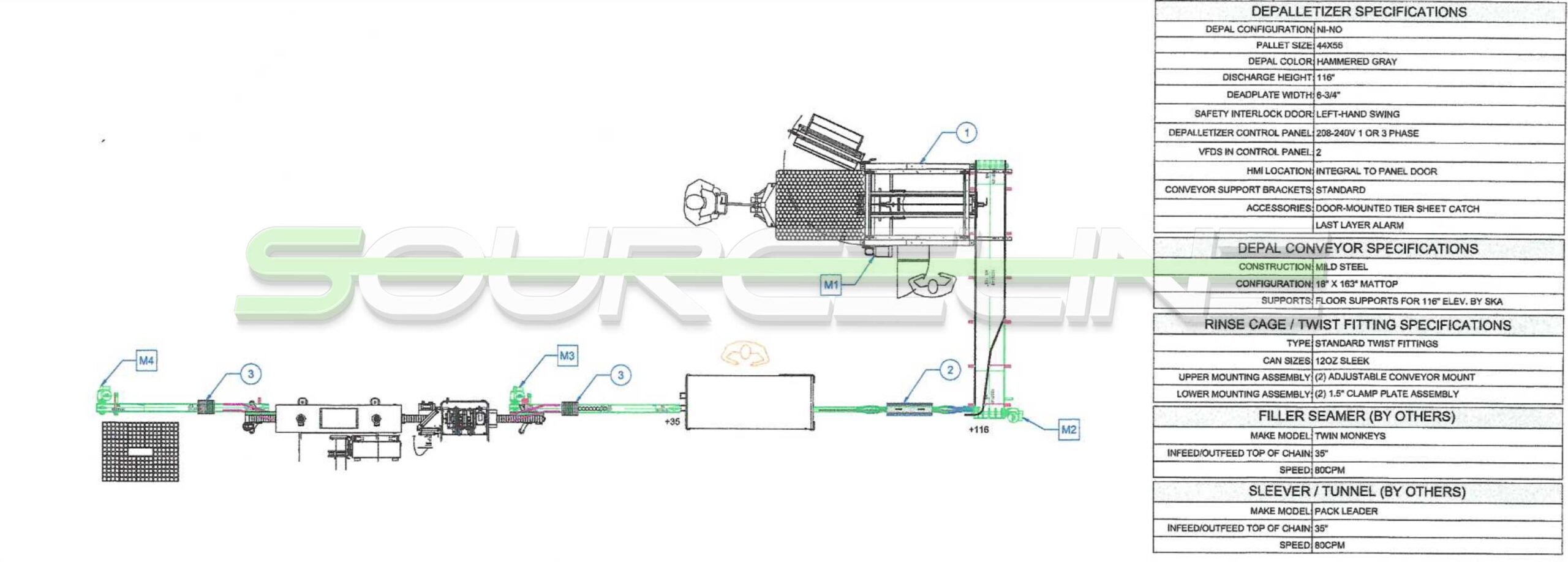

Dual Lane Can Filling System features PLC controlled with HMI touch screen, Fully adjustable timers for system functions, Fully adjustable fill levels, CIP/SIP for fill system, Wash down-compliant sensors, pneumatics, enclosure, and decking. The system also includes a Depalletizer, Rinse Cage, Videojet Coder, Check Weigher, 60″ rotary accumulation table, shrink sleeving system, and steam boiler (see equipment list for more details)