Used 5 Gallon Water Bottling Line

| Condition | |

| Category | Complete Lines |

| Manufacturer | CapSnap, Ozone Solutions, SWF, Triple S, Videojet |

| Model | 850 |

| Industry | Beverage |

| Speed | 850 BPH |

| Location | North America |

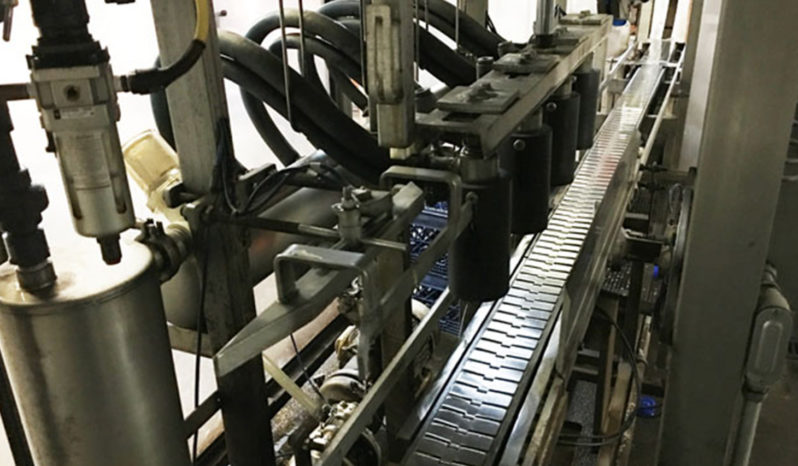

The Used 5 Gallon Water Bottling Line series automatically washes, fills and caps 3 to 5 gallon bottles of virtually any style simultaneously, without the need for any hand-sorting or equipment adjustments. This system is a Model 850 that washes, fills, caps and stacks up to 850 bottles an hour. All CapSnap water bottling equipment meets or exceeds IBWA, and FDA standards. This system is also NSF food-zone component certified. This Used 5 Gallon Water Bottling Line is accompanied by global support service for water bottling equipment, offering spare parts and field servicing (emergency shut down, routine and preventative maintenance) options for water bottling plants.

This system washes, fills and caps and stacks up to 850 bottles an hour. Available Now

This Used 5 Gallon Water Bottling Line is synonymous with quality and every piece built was meant to last for decades. These machines are known for their reliability, durability, and ease-of-operation. We offer many options and solutions so that you can custom-build the HOD water bottling plant that you need without the custom costs.

- Higher PSI

- More GPM

- Better Spray Patterns

- Cleaner Bottles

CapSnap Bottle Decapper

Automatically removes and discards caps from empty 5-gallon bottles at speeds up to 1,800 BPH. Designed for over conveyor mounting. Customized to fit top-of track height requirements. Right or left hand cap discharge models available. Bottle-backup sensor prevents back-up on discharge conveyor. Built-in sensor allows bottles without caps to pass through. Audible alarm sounds if cap is not removed completely. Control panel with touch-screen. Requires minimum accumulation of 10’ power conveyor for proper operation

CapSnap 5 Gallon Bottle Washer, Auto Load, Auto Unload

Internal and external spray patterns and nozzles to maximize coverage. Programmable Logic Controller (PLC) and touch screen. Cannister solution filtration. Sloped floor in wash and rinse tanks. Safe design to protect pinch points. Solution- and water-level monitoring in all tanks. Inlet protection to pumps. Convenient single-point drain. Rinse and sanitizing options. Catch cap plugs. LED lights

Triple S Wash Water Boiler, Natural Gas

The TSM hot water boiler produces 230 degree f. Hot water that is circulated in a closed pressurized loop through the heating water side of a plate & frame heat exchanger. The heat exchanger transfers the heat from the heating water to the product as it flows through the plates on the product side of the heat exchanger. This system is ideal for heating sanitary liquids. All of the components in contact with the sanitary liquid will be constructed of type 304 or type 316 stainless steel.

5 Gallon Filler Capper 4 Spout Cap Sorter

Inline and Side-shift filling stations. Variable Frequency Drive (VFD) to minimize overfill and waste. Robust and durable components. Bottle counting and bottle stops. PLC adjustable parameters for speed, flow rate, and accuracy

Stainless Steel & Lexan Enclosure

Hess Ozone System with Ozonator and Contact Tank

Hess Machine Ozone Generators were designed for use in the bottled water industry. These ozone generators produce ozone from dry air with an integrated air dryer, meaning only compressed air and electricity are required for operation.

Lot, Stainless Steel Interconnecting Bottle Conveyors

Videojet Ink Coder

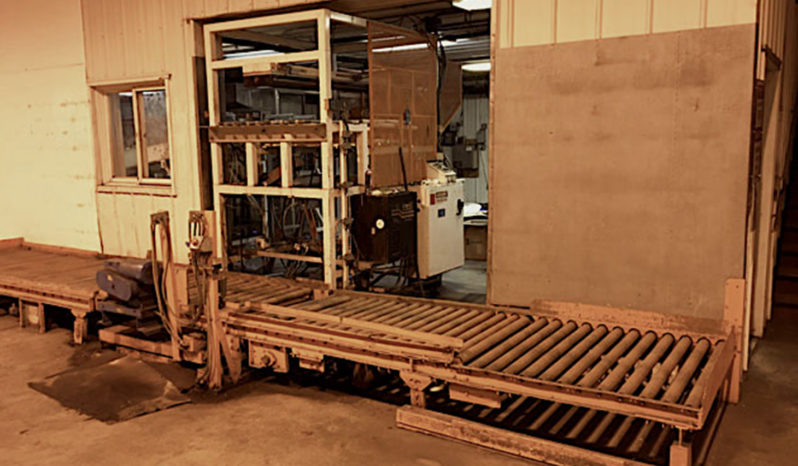

SWF McDowell Automatic Rack Loader

Lot, Full Pallet Conveyors

Core Features:

- Pneumatically actuated, spring loaded neck grippers hold bottles securely, allowing for higher pressure wash spray

- Direct-drive gearmotor with VFD over-torque

- Overhead hopper with vibrator and low-level switch

- Air regulators at presser-belt and cap-chute foot

- New methods of water conservation and wash solution filtration

- Advanced nozzle technology provides spray patterns that cover all parts of the bottles

- New nozzles and carrier design leads to increased PSI and GPM

- Spinner bowl to orient caps into correct position

- Adjustable rod-style open cap chute for easy cleaning

Highlights

- Higher PSI

- More GPM

- Better Spray Patterns

- Cleaner Bottles

Do you have a Used 5 Gallon Water Bottling Line or Similar Equipment?

Allow SOURCELINE to put money back into your pocket by clearing out your Surplus Equipment or Idle Assets from complete lines like this Used 5 Gallon Water Bottling Line to entire manufacturing facility liquidations.

Click the button below to let us know what you have available.

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086MAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530

EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comOFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)

PHONE

Sales: (800) 215 7115

US: (484) 553 9086

UK: +44 (0) 0800 368 9086EMAIL

sales@sourcelinemachinery.com

info@sourcelinemachinery.comMAILING ADDRESS

P.O. Box 285

Kutztown, PA 19530OFFICE HOURS

Mon – Fri (9am – 5pm EST)

Sat & Sun (By Appointment)